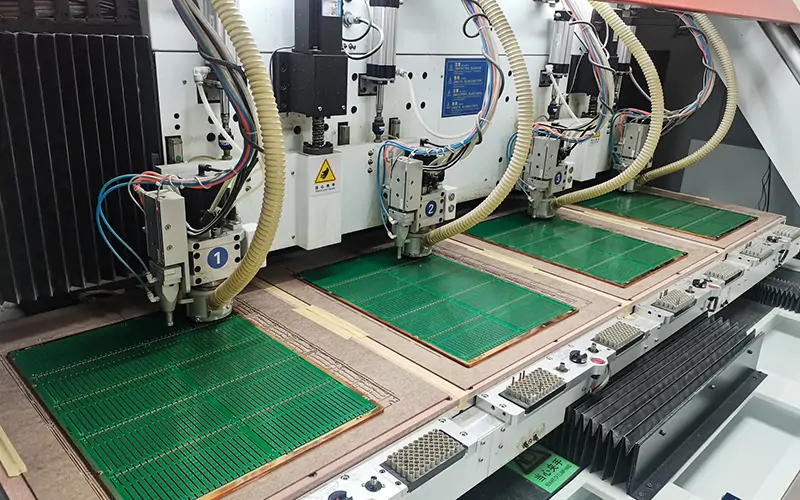

Automotive PCBAs are widely used in various automotive electronic systems. As automotive technology advances, especially with the rise of electric and smart cars, the complexity and functionality of automotive PCBAs are increasing.

At HRPCBA, we have innovated our technology to meet the ever-changing market demands, focusing on improving the quality, reliability and safety of PCBAs.

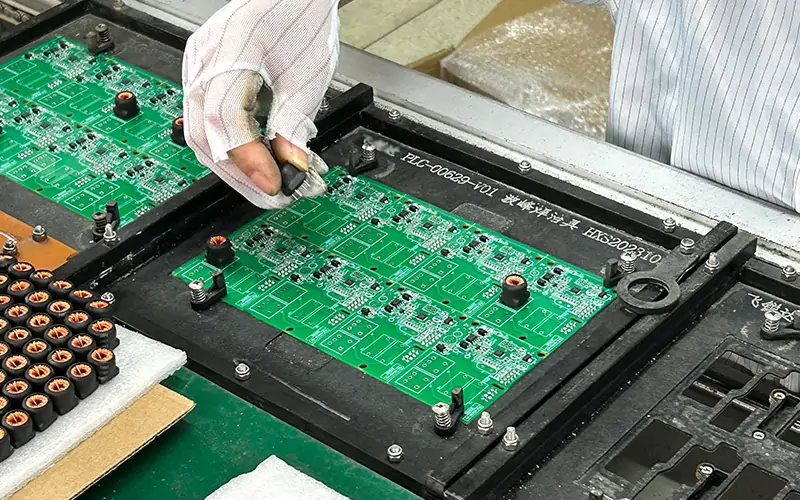

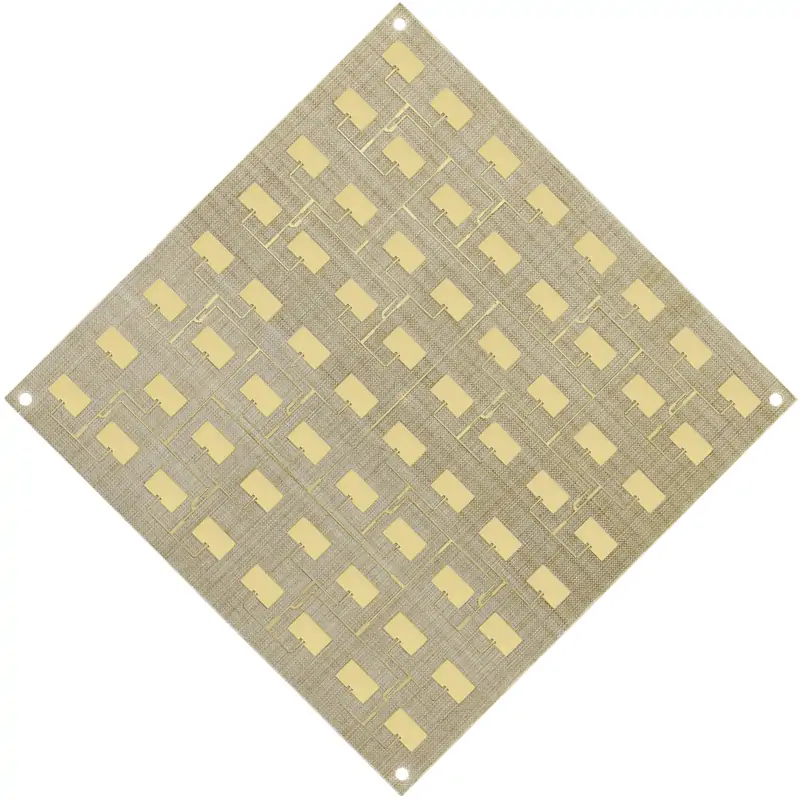

Use of high-quality substrate materials and components to ensure the reliability and durability of PCBAs under various environmental conditions.

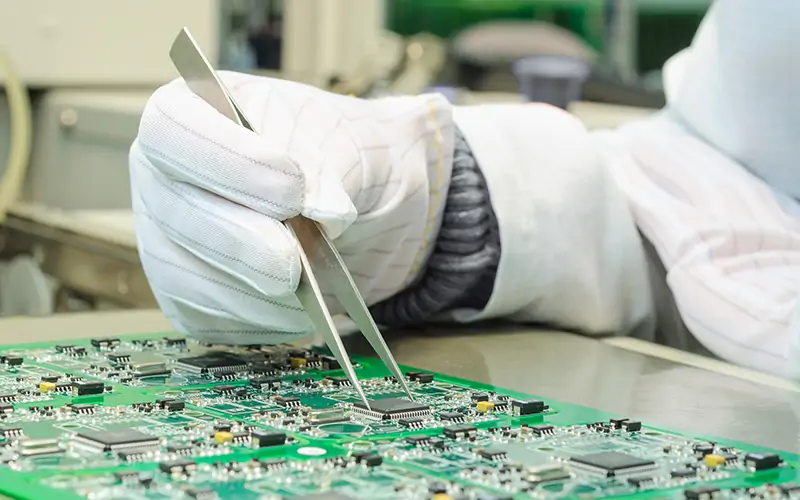

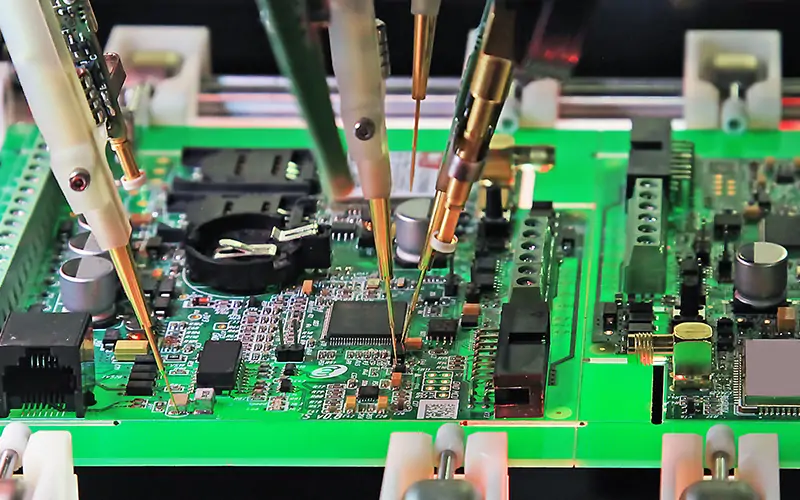

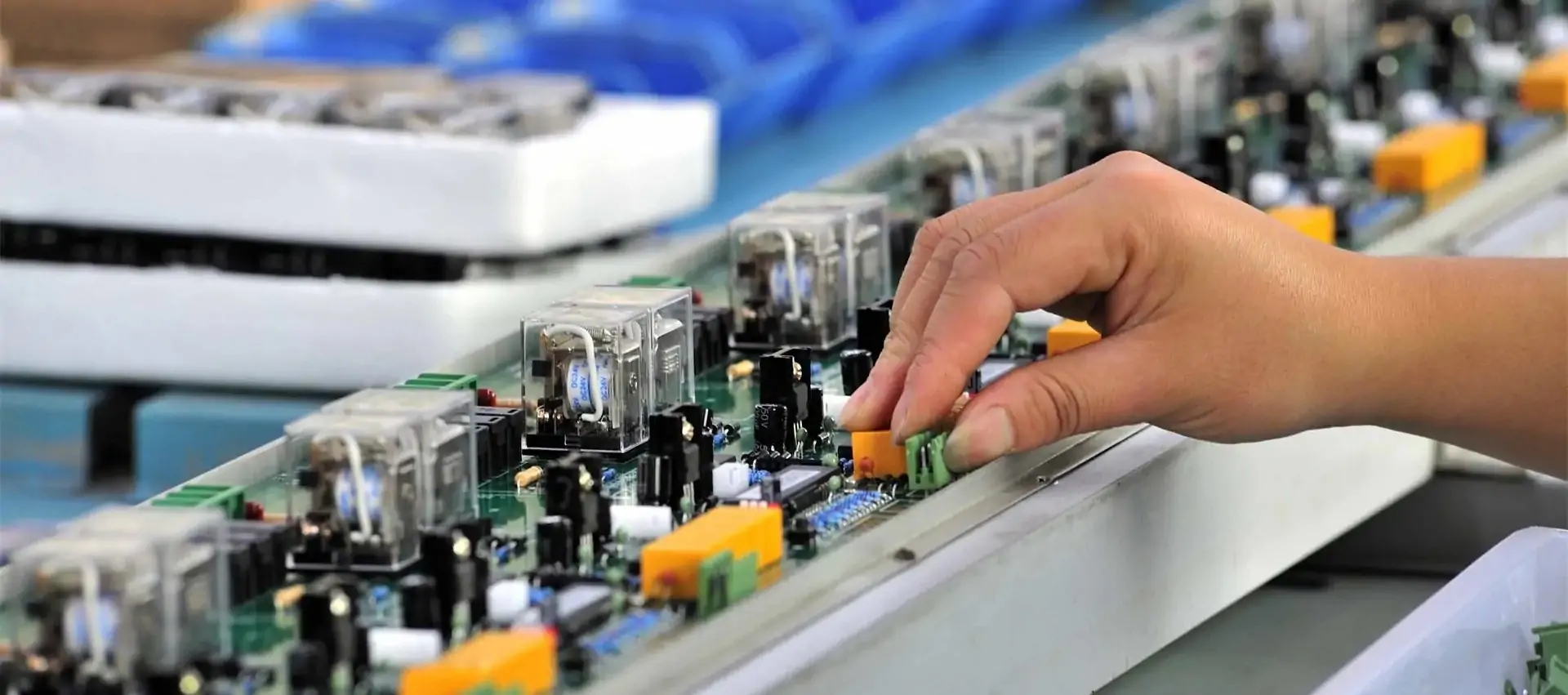

HRPCBA implements a comprehensive testing and quality control process, including functional, environmental and electrical testing, to ensure the performance of each component.

HRPCBA produces PCBAs based on customer gerber documentation, ensuring that the PCBA design is compatible with existing automotive electronic systems and modules.

HRPCBA follows automotive industry design and manufacturing standards (e.g. TS 16949 and ISO 26262) to ensure PCBA safety and compliance.

Used in engine control units (ECUs), electric vehicle power management systems, etc., responsible for controlling and optimising the vehicle's power output.

Includes navigation, audio and infotainment systems that provide multimedia features and driving information.

Used for airbag control system, electronic stability control (ESC), anti-lock braking system (ABS), etc. to ensure driving safety.

Including automatic parking, lane keeping, collision warning and other functions to enhance driving safety and convenience.

Checks component position and soldering quality on the PCB to ensure that all functional modules work properly and meet design requirements.

Perform environmental tests such as temperature, humidity, and vibration to ensure the reliability of the PCBA under extreme conditions, as well as insulation and grounding tests to ensure electrical safety.

Evaluate the durability of products through accelerated aging tests to ensure their reliability in long-term use, and test the performance of PCBAs under electromagnetic interference and radio frequency interference.

Verify PCBA compliance with automotive safety standards to protect occupant safety, and test embedded software and firmware to ensure proper function and effective interaction with hardware.

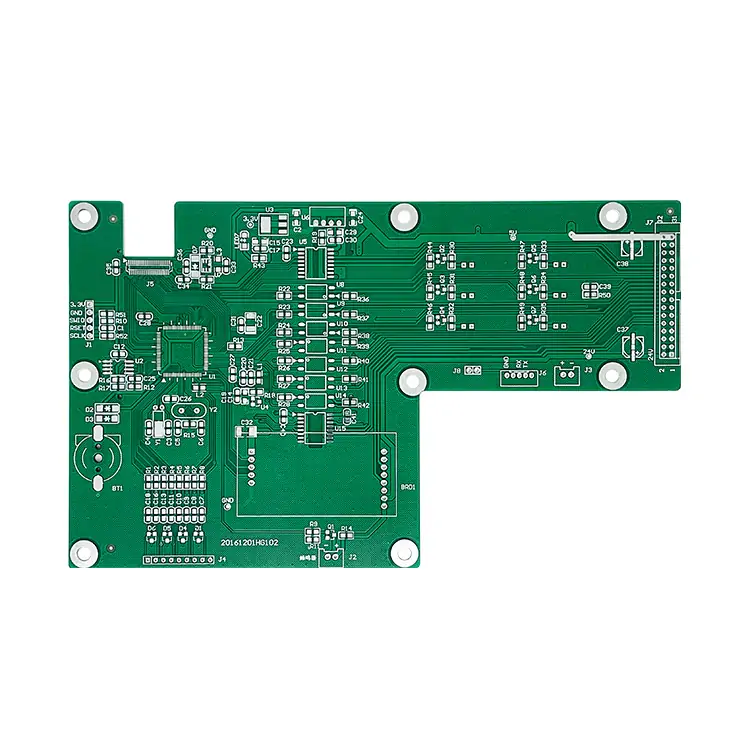

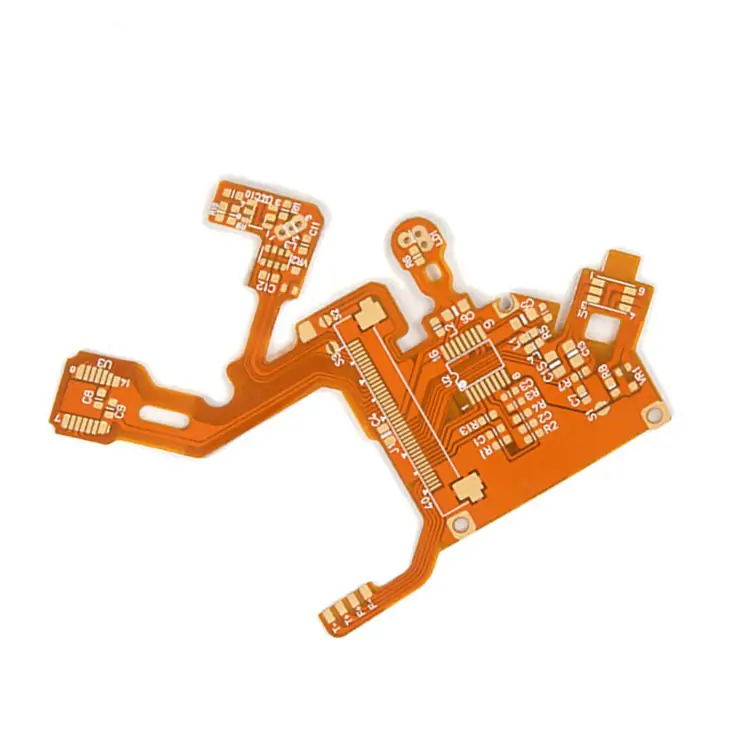

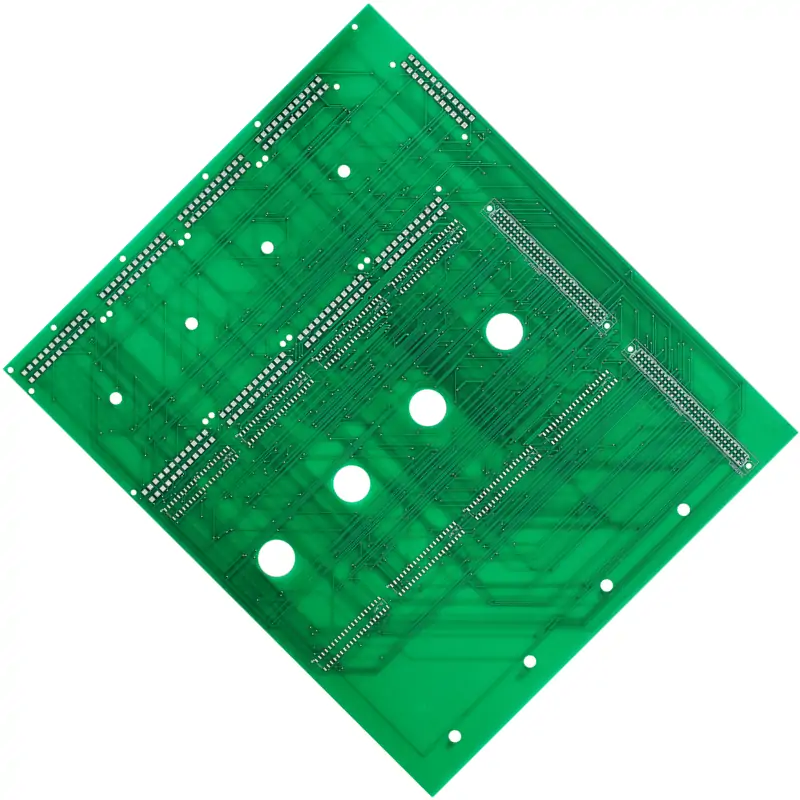

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.