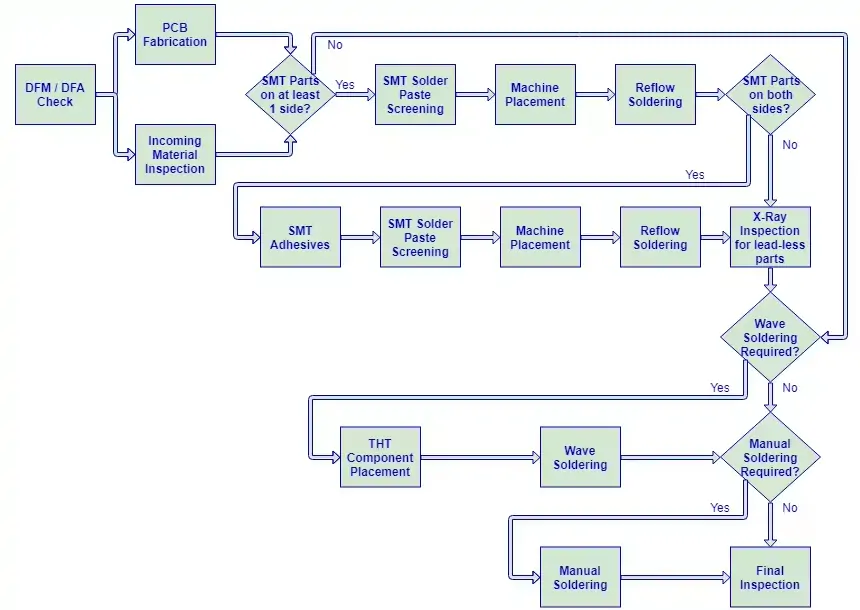

BGA PCB Assembly process is: printing solder paste on the PCB, mounting the BGA chip to the PCB pads, reflow soldering to connect the solder balls to the pads, followed by testing and rework.

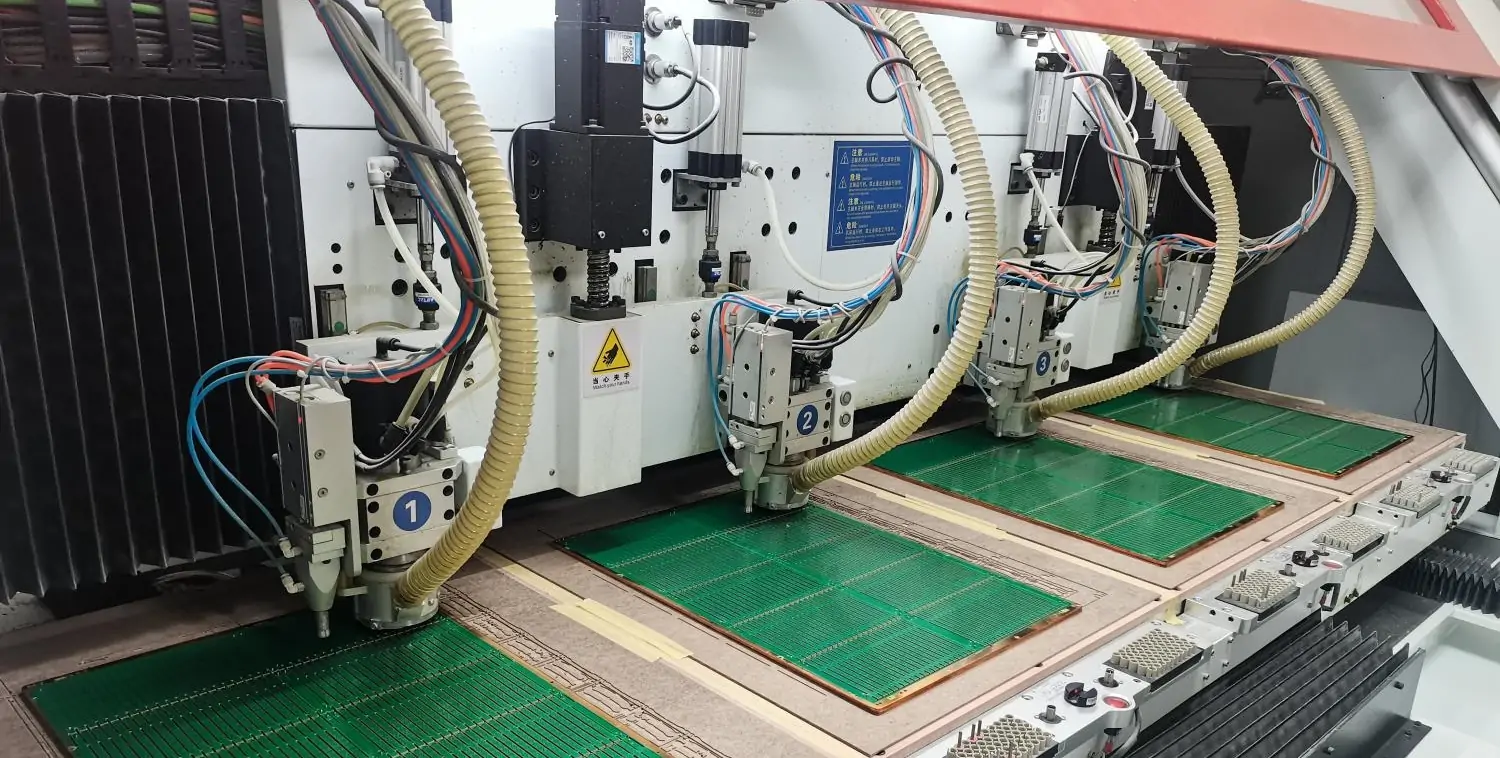

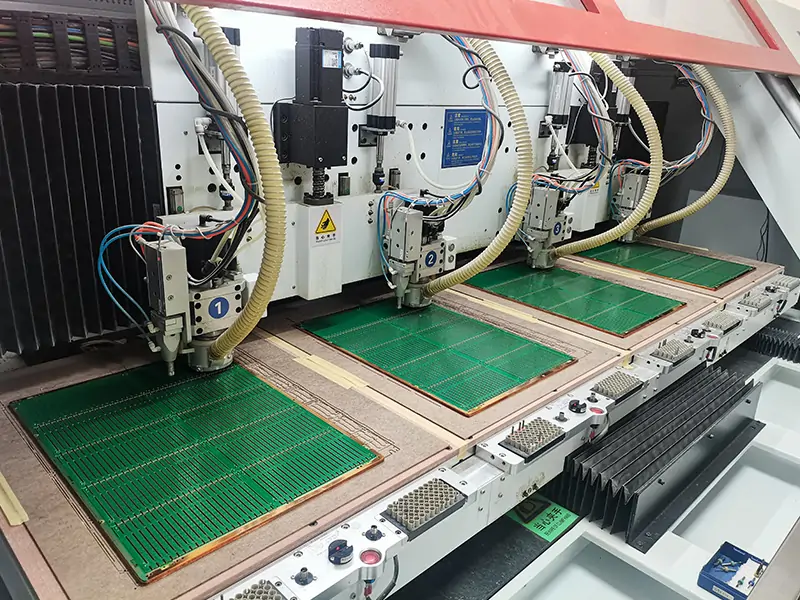

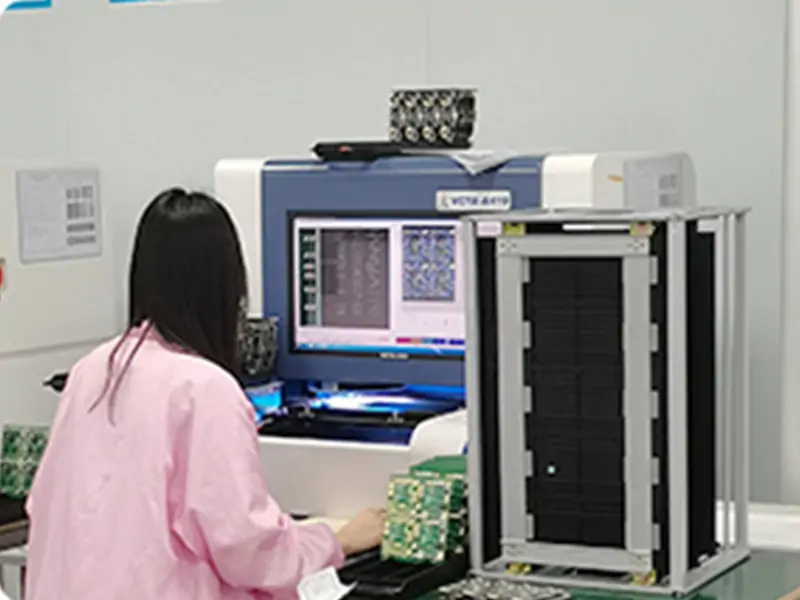

Our engineering team and company founders are highly skilled and respected with over 25 years of industry experience, which ensures that you will receive a PCBA product that perfectly meets your requirements. Our state-of-the-art SMT and THT production lines provide a full range of services from PCB design and component sourcing to assembly and testing, ensuring fast delivery of high quality products.

BGA (Ball Grid Array) assembly is a type of surface mount packaging used for integrated circuits (ICs) that utilizes an array of tiny solder balls arranged in a grid on the underside of the component. These solder balls replace traditional pins or leads and serve both as electrical and mechanical connections to the printed circuit board (PCB).

Surface Mount Devices (SMD, Surface Mount Device) are usually smaller than through-hole components, which allows the equipment to be more compact.

SMT equipment can be automated, increasing productivity gains.

Higher circuit densities can be realized as components can be mounted directly on the surface of the PCB.

High degree of automation reduces labor costs during production

SMT technology supports the mounting of components on both sides of the PCB, further increasing circuit complexity and functional integration.

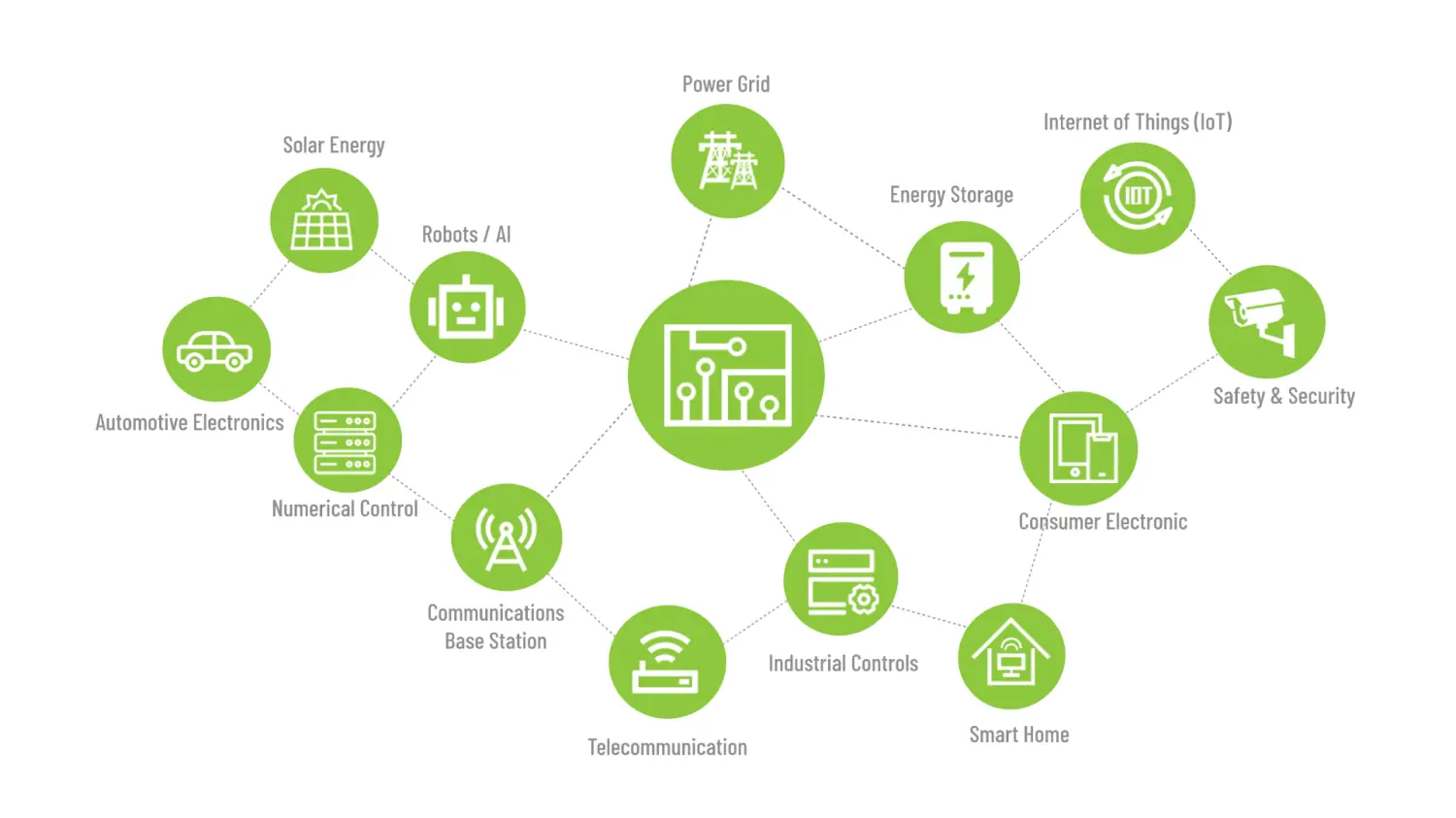

Medical electronics, automotive electronics, military electronics, industrial electronics, consumer electronics, communication electronics, smart home, ITO, security electronics, etc.

Provide your idea and requirements for your product

Brainstorming with each otherand defining the product

Design schematic diagram

Layout and simulation

Prototyping and sample Testing

Confimmation sample we will arrange bulk production

With 25 years of development, HRPCBA has become an excellent PCB and PCBA assembly manufacturer. We provide ourcustomersWith PCB solutions and services worldwide.especially more than 90%Printed circuit board are exported tooversea market.

One-Stop Contract Manufacturing Services

Competitive Price in Peer Industry

4 Hours Quotation,2 Days Delicery,24 Hours customer Services

Strict Quality Control With 100%

Sales Network Covers Over Morethan 180 Countries And Regions

Efficient and Professional International Sales Team