We have introduced modern production and testing equipment, as well as advanced technology to provide complex design solutions such as High Density Interconnect (HDI) and multilayer boards to meet the diverse needs of our customers. We also provide one-stop service for quick samples, small and medium quantities and large quantities for our customers.

HRPCBA has a number of qualification certificates such as ISO, IATF16949, CQC, UL, ROHS, and so on. We strictly follow the standards set by IPC Product Assurance Council for production. We guarantee the high quality of our products while ensuring timely delivery.

At the same time, we focus on environmental protection and sustainable development, and are committed to providing our customers with green electronic manufacturing services where high quality and environmental protection go hand in hand.

If you are still looking for suppliers who can deliver on time and high quality products for your project, you are welcome to contact us for more information about HRPCBA. We will be your reliable pcb supplier.

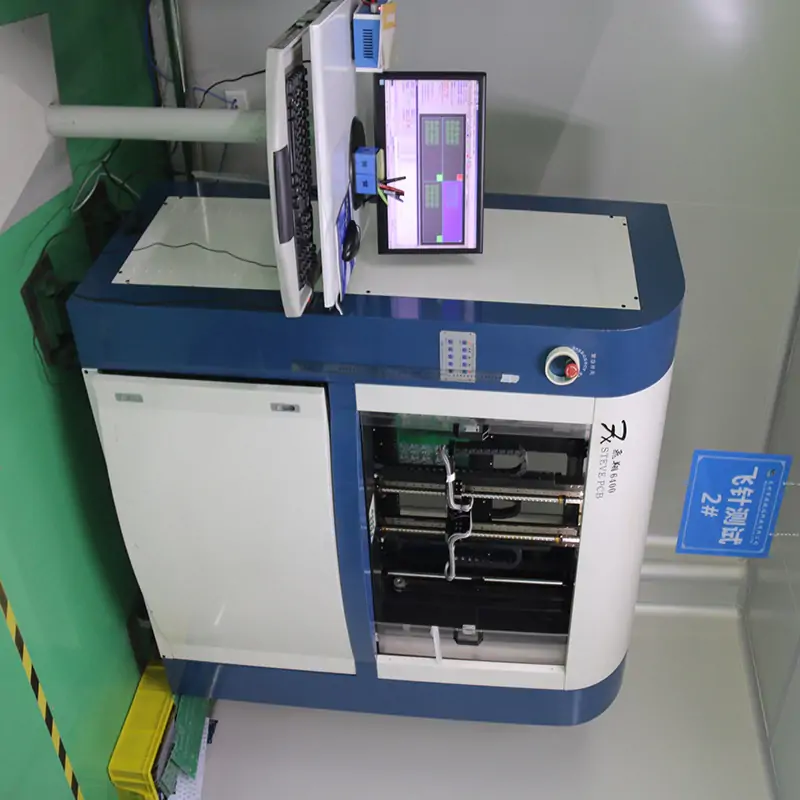

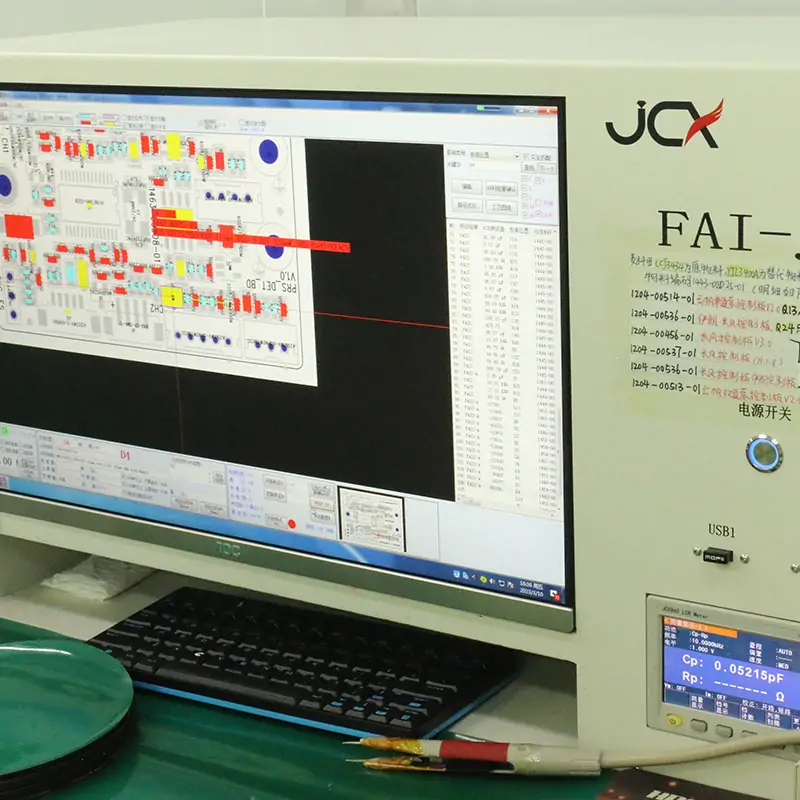

Fast detection speed and high precision, can complete a comprehensive inspection of the entire PCB board in a short period of time, can also find small defects, will not cause physical damage to the PCB.

It is possible to detect hidden solder joints inside PCBAs, soldering under BGA packages, structural defects inside components, and other problems that cannot be directly observed by the naked eye.

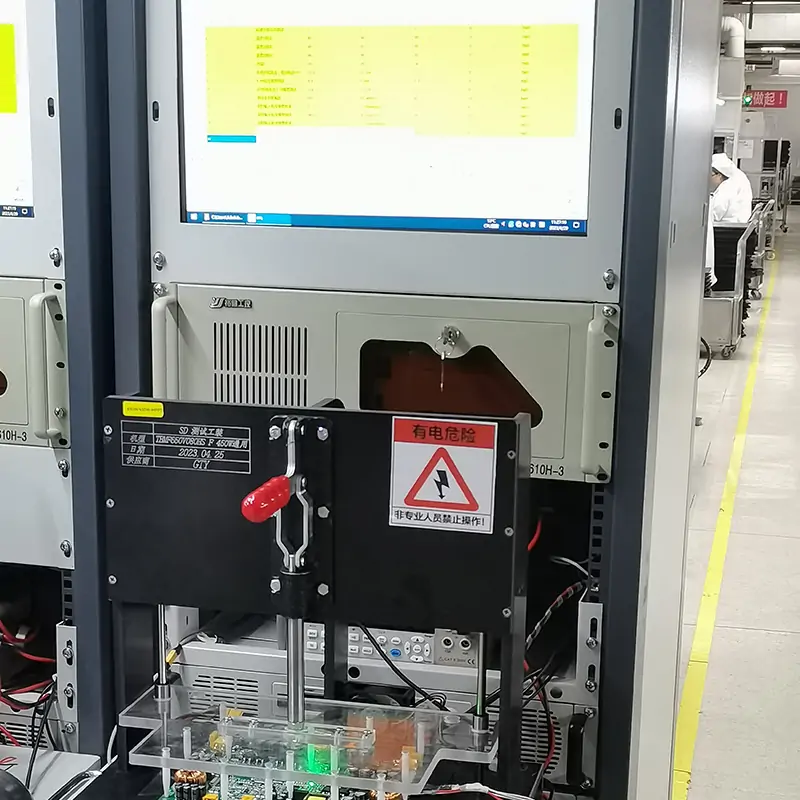

It can directly and accurately detect defects that affect the electrical performance of the PCB, and also has good detection ability for the line problems hidden in the internal layer of the PCB, to ensure that the PCB meets the design requirements in terms of electrical aspects.

Efficiently performs comprehensive functional screening of PCBAs, quickly locates failure points, and for mass-produced PCBAs, significantly improves production efficiency and product quality, effectively reduces production costs, and ensures the correctness of the assembly process.

The QA (Quality Assurance) inspection of PCBA is a crucial step in ensuring that the PCBA meets quality requirements. It checks the appearance of the components and whether there are any missing or incorrectly installed components.

FAI inspection can detect production problems early, ensure product quality, improve production efficiency, facilitate quality traceability, and enhance customer confidence, which is of great significance to production.

In the PCB manufacturing process, the quality of the bare board can be ensured through AOI, ET and other means. After assembly, through ICT, FCT and other inspection methods to confirm the integrity of the product function, effectively reduce the defective rate, to ensure the quality of the final product is reliable.

The inspection can quickly screen out qualified PCB or PCBA products, reducing the time spent on the production line and subsequent processing due to nonconforming products.

Early detection of PCB and PCBA defects can be repaired and reworked in a timely manner during the production process, avoiding the problem after the product has been completed assembly or delivered to the customer, thus greatly reducing the cost of repair and rework.

| Layer | quick turn Prototype | unual time Prototype | Mass productions (above 30 m2 ) |

| 2 | 24 hours | 3-4 days | 8-10 days |

| 4 | 48 hours | 5-6 days | 10-12 days |

| 6 | 72 hours | 6-8 days | 12-14 days |

| 8 | 72 hours | 8-10 days | 14-16 days |

Each customer has a dedicated customer service and engineering team to address pre and post sales issues.

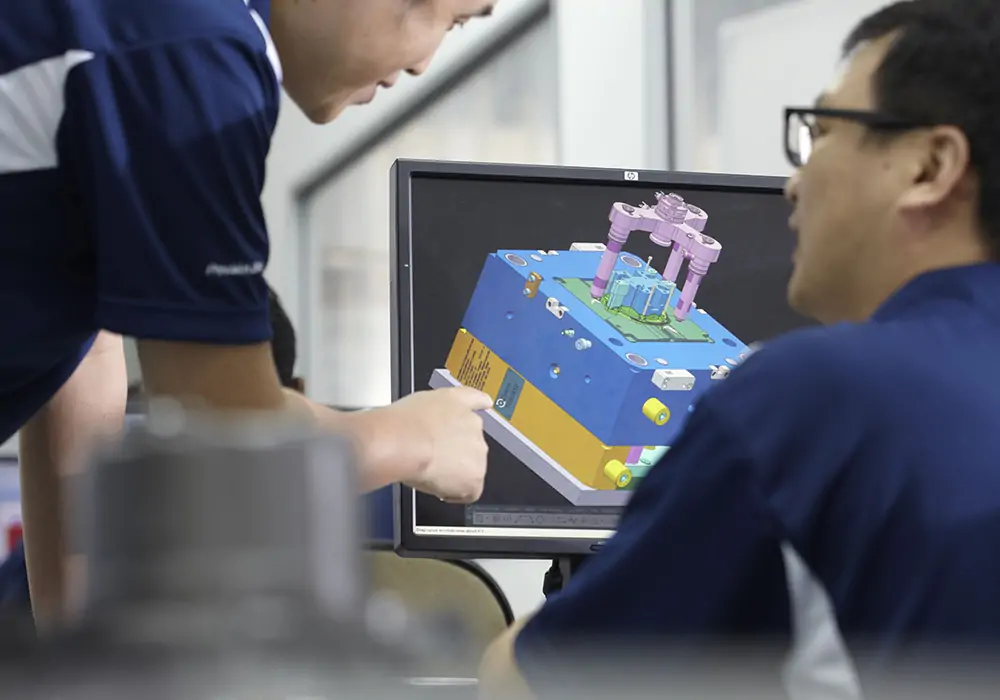

We can achieve your electronic products from schematic design, PCB and assembly making, and METAL & PLASTIC INJECTION MOLDING for your electronic products.

We have established a strong global electronic component supply chain, while China's low-cost, industry-wide Electronic component supply chain services have strong competitiveness in the global market.

A team of engineers with over 25 years of industry experience will provide the best replacement solution based on your ideas and requirements.

Usually we need you to provide the following documents:

Gerber File, Drill File, Pick & Place File, BOM list. If more support is needed, our engineers can assist you in preparing these files.

Production lead time depends on the type of PCB, complexity and order quantity. Generally the production lead time is 3-4 days for prototype and 8-16 days for mass production. For urgent orders, we can provide expedited service, the fastest delivery of prototypes within 24 hours. You can contact our sales team to confirm the detailed delivery time.

All data files provided by customers will be kept strictly confidential, you can also sign NDA (Non-Disclosure Agreement) with us.

The choice of PCB type depends on your application requirements. We will have professional engineers and sales team to follow up your project and recommend the right PCB type according to your needs.

For more questions, you can contact online customer service for consultation.