We have introduced modern production and testing equipment, as well as advanced technology to provide complex design solutions such as High Density Interconnect (HDI) and multilayer boards to meet the diverse needs of our customers. We also provide one-stop service for quick samples, small and medium quantities and large quantities for our customers.

HRPCBA has a number of qualification certificates such as ISO, IATF16949, CQC, UL, ROHS, and so on. We strictly follow the standards set by IPC Product Assurance Council for production. We guarantee the high quality of our products while ensuring timely delivery.

At the same time, we focus on environmental protection and sustainable development, and are committed to providing our customers with green electronic manufacturing services where high quality and environmental protection go hand in hand.

If you are still looking for suppliers who can deliver on time and high quality products for your project, you are welcome to contact us for more information about HRPCBA. We will be your reliable pcb supplier.

With advanced production facilities, a production workshop area of 20,000 square meters and a production capacity of 50,000 square meters/month, we are able to efficiently satisfy our customers' needs, whether it's a small trial run or a large volume mass production.

With a state-of-the-art production facility with a production base of 5,500 square metres and a daily capacity of 22 million solder joints, we are able to efficiently meet our customers' needs, whether it is a small trial run or a large volume production.

Our PCBA products cover a wide range of types and are widely used in fields such as consumer electronics, automotive electronics, industrial control, medical devices, communication equipment, and IoT. We support single-layer, double-layer, multi-layer, HDI, high-frequency, and flexible and rigid-flex boards.

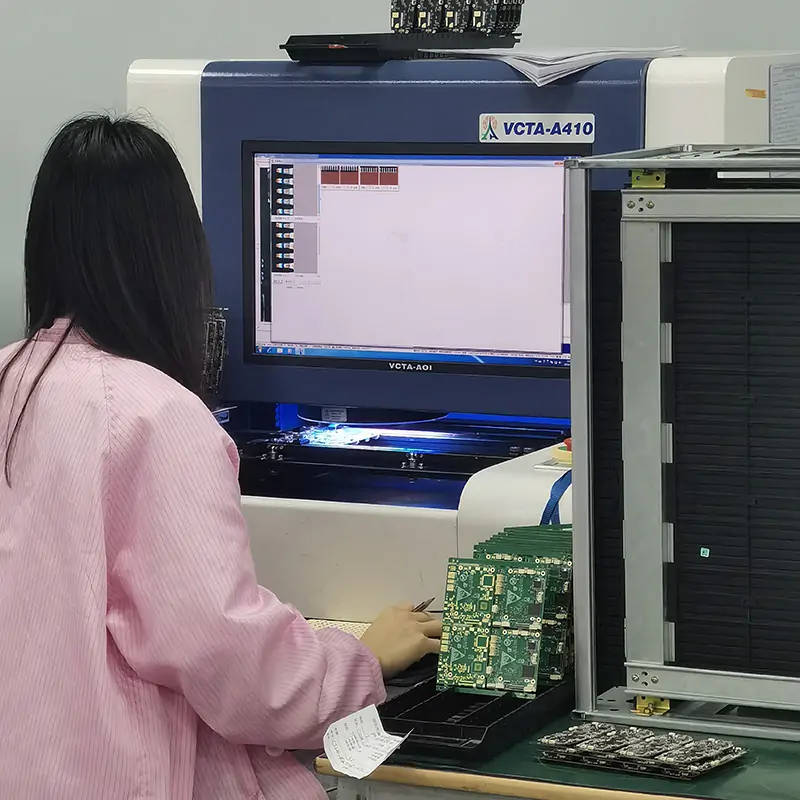

Equipped with AOI optical inspection, X-Ray inspection, functional testing (FCT), and environmental reliability testing, we ensure soldering precision and electrical performance.

Able to respond quickly to customer needs, provide flexible delivery cycle, the fastest can be realized within 24 hours to deliver samples.

At HRPCBA , we provide one-stop service, with experienced engineers and professional sales to follow up your project, to ensure the smooth production and timely delivery of orders.

HRPCBA support single-layer, double-layer, multi-layer, HDI, high-frequency, and flexible and rigid-flex boards to meet various complexity and functionality requirements, suitable for applications ranging from everyday consumer goods to high-precision industrial equipment.

PCB assembly is characterised by high precision, high density and versatility, adapting to the needs of modern electronic products. Through automated equipment to improve production efficiency, we flexibly respond to small-lot and high-volume production, while implementing strict quality control, such as AOI inspection, X-RAY test and functional test, to ensure the reliability and stability of the products.

PCBA is widely applicable in various fields, including consumer electronics, automotive electronics, industrial control, medical devices, communication equipment, and IoT, meeting the functional and performance requirements of different products."

Welding in PCB assembly is crucial for ensuring connection quality and reliability, using methods like reflow and wave soldering, while enhancing product durability and production efficiency through automation.

| Quantity (pieces) | <5 | 6 - 1000 | 1001 - 10000 | > 10000 |

| Lead time (days) | 7 | 14 | 21 | To be negotiated |

Each customer has a dedicated customer service and engineering team to address pre and post sales issues.

We can achieve your electronic products from schematic design, PCB and assembly making, and METAL & PLASTIC INJECTION MOLDING for your electronic products.

We have established a strong global electronic component supply chain, while China's low-cost, industry-wide Electronic component supply chain services have strong competitiveness in the global market.

A team of engineers with over 25 years of industry experience will provide the best replacement solution based on your ideas and requirements.

Usually we need you to provide the following documents:

Gerber File, Drill File, Pick & Place File, BOM list. If more support is needed, our engineers can assist you in preparing these files.

Production lead time depends on the type of PCB, complexity and order quantity. Generally the production lead time is 3-4 days for prototype and 8-16 days for mass production. For urgent orders, we can provide expedited service, the fastest delivery of prototypes within 24 hours. You can contact our sales team to confirm the detailed delivery time.

All data files provided by customers will be kept strictly confidential, you can also sign NDA (Non-Disclosure Agreement) with us.

The choice of PCB type depends on your application requirements. We will have professional engineers and sales team to follow up your project and recommend the right PCB type according to your needs.

For more questions, you can contact online customer service for consultation.