The PCBA of a charging post is responsible for controlling and managing the charging process to ensure safe and efficient charging of electric vehicles.

As the electric vehicle market continues to grow, so do the technical requirements for charging pile PCBAs. HRPCBA has specialised in the PCBA industry for over 25 years, and our engineering team and founders are highly respected for their extensive industry experience and technical excellence.

The design is optimized to achieve efficient energy conversion, reducing energy loss and improving charging efficiency to ensure fast charging performance.

Integrated with various safety features, such as overload, short circuit, over-temperature, and over-voltage protection, to ensure safety during the charging process and prevent electrical failures.

Utilizes high-quality components that can manage high current and high voltage, ensuring the stability and reliability of the PCBA under fast charging and high power output conditions.

Supports efficient communication with electric vehicles and charging management systems, using standardized protocols such as Open Charge Point Protocol (OCPP) for data transmission and remote monitoring.

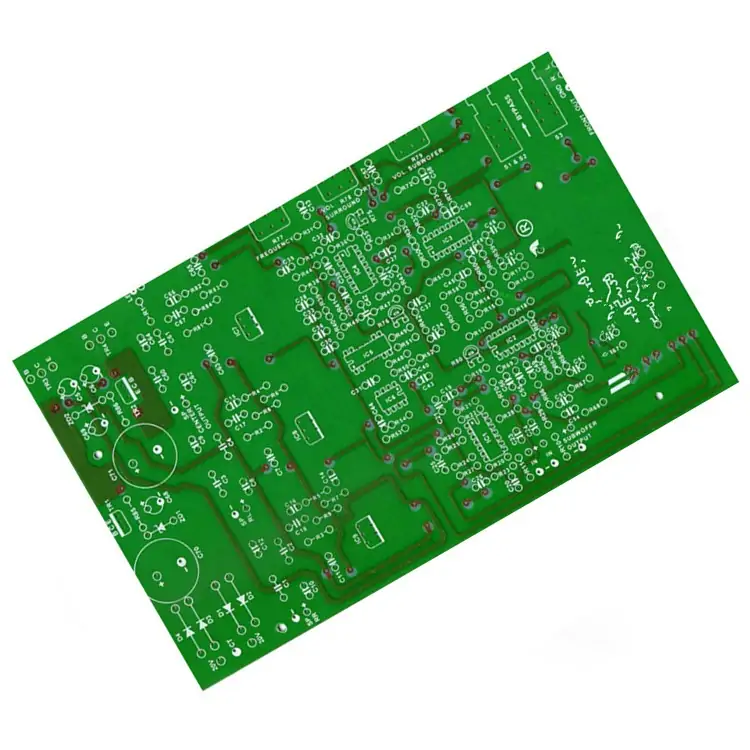

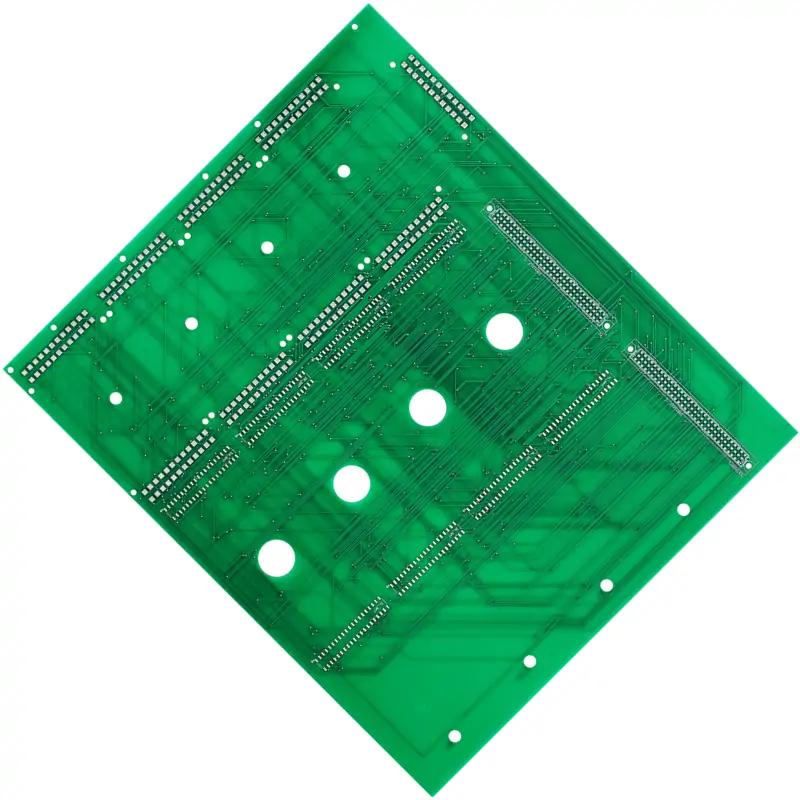

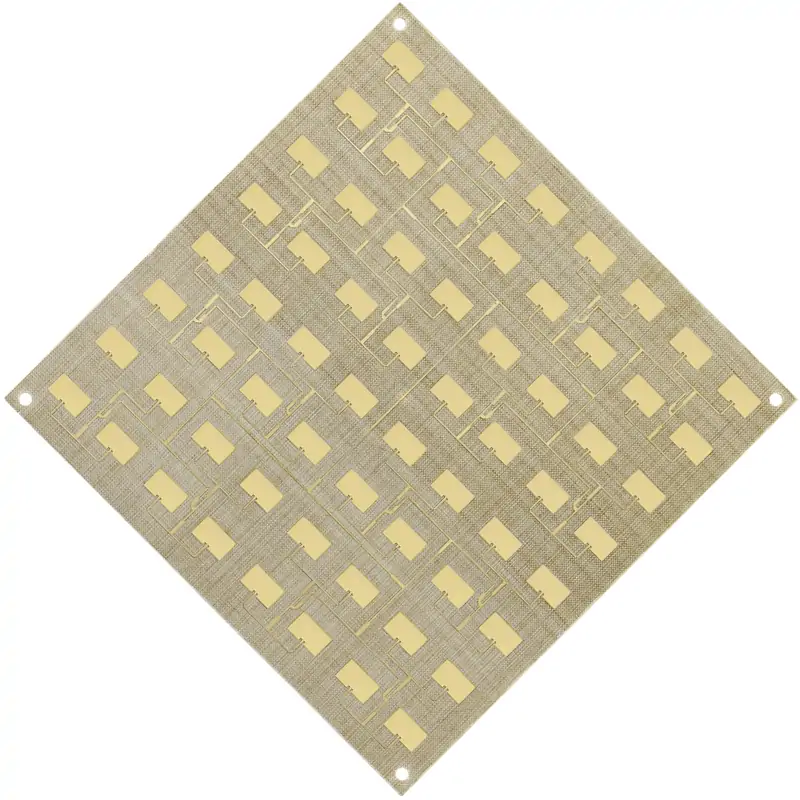

Select high quality PCB substrate materials (e.g. FR-4 or high frequency materials) suitable for high current and high voltage applications. Use solder that meets environmental standards (e.g. RoHS) to reduce the impact on the environment.

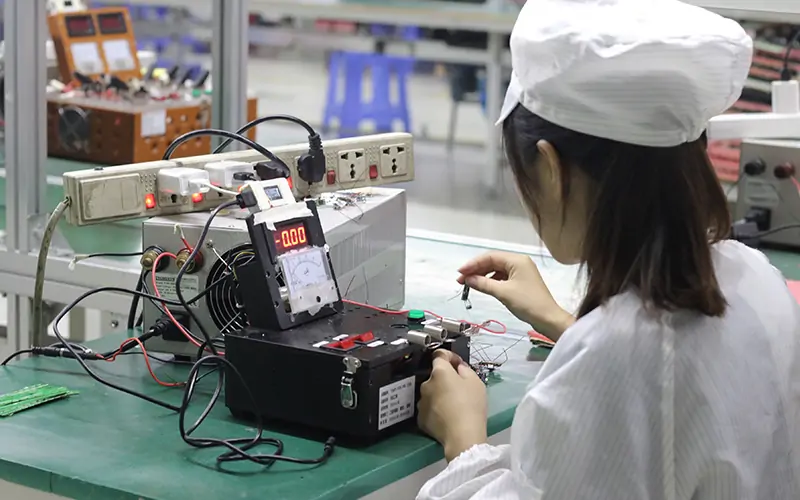

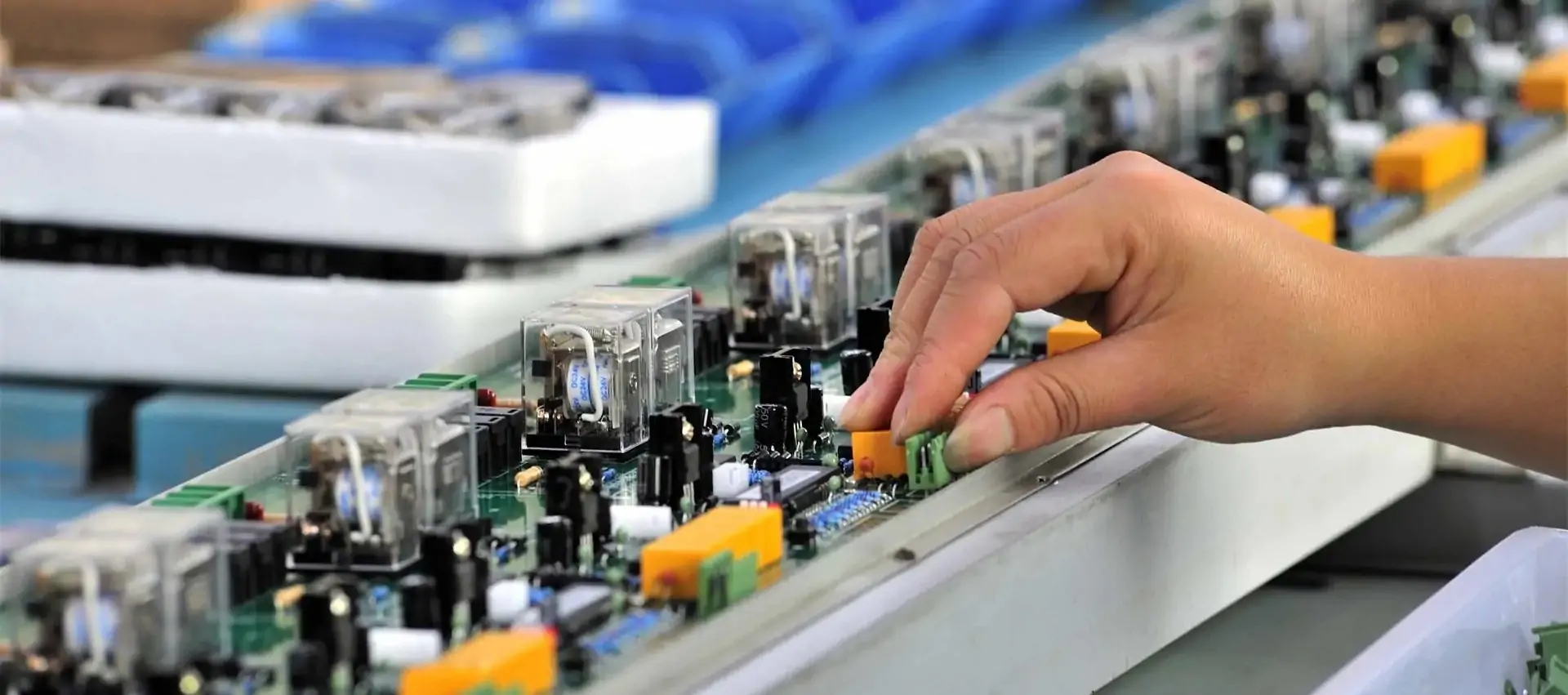

Incoming material inspection to ensure all components meet specifications and quality standards. Electrical testing, functional testing and automatic optical inspection (AOI) are performed after completion of soldering.

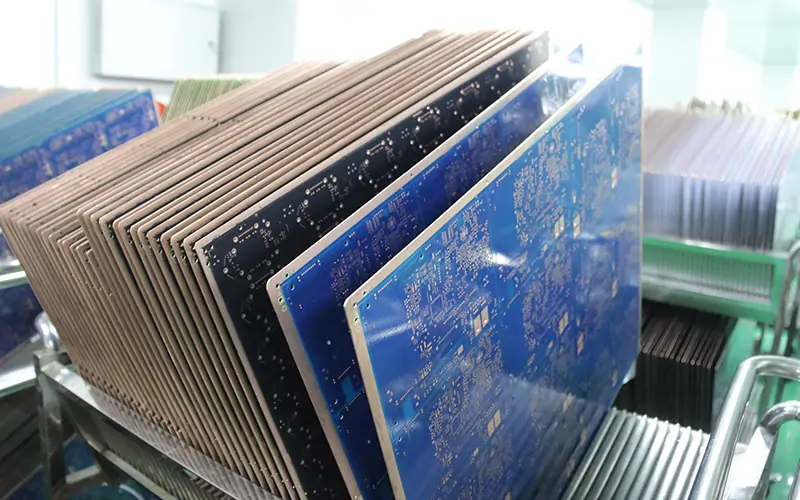

PCBs are manufactured using high-precision manufacturing processes. Component placement is carried out using automated SMT equipment. The appropriate soldering process is selected according to the needs of different components.

Comply with industry standards (e.g. ISO 9001, ISO 14001, IEC, UL, etc.) to ensure product safety and reliability. And keep records of all production and testing processes for traceability and quality management.

Function: Typically used for LED indicators, power conversion modules and heat sinks to ensure effective heat dissipation during high power charging.

Function: Used in power management systems, charge controllers for electric vehicles and other critical electronic control units to improve overall performance and reliability.

Function: Communication modules for charging posts, such as those supporting OCPP (Open Charge Point Protocol), ensure efficient data communication with electric vehicles and charge management systems.

Function: Includes charge controller and inverter circuits responsible for converting grid power to voltages and currents suitable for EV charging.

Verify that all functions of the PCBA are operating properly, including power management, communication modules and charging control.

Insulation Test、Grounding Test、Voltage and Current Test.

Over-voltage and over-current protection test、Thermal Protection Testing.

Automatically detects the soldering quality and component position on the PCB.

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.