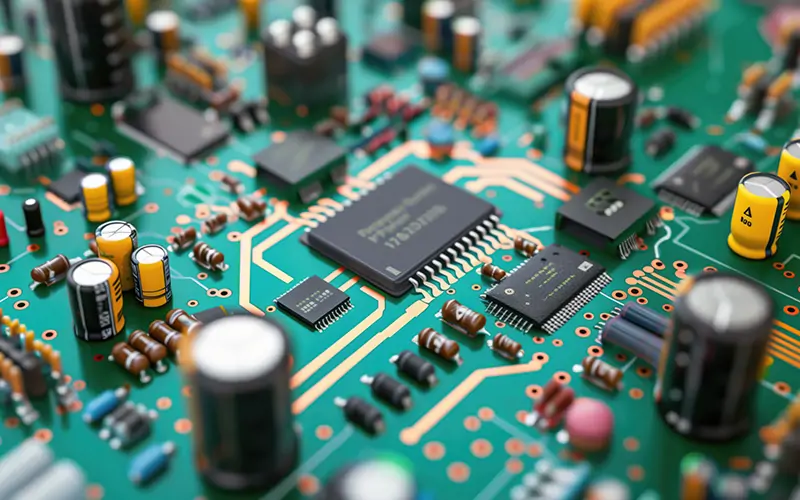

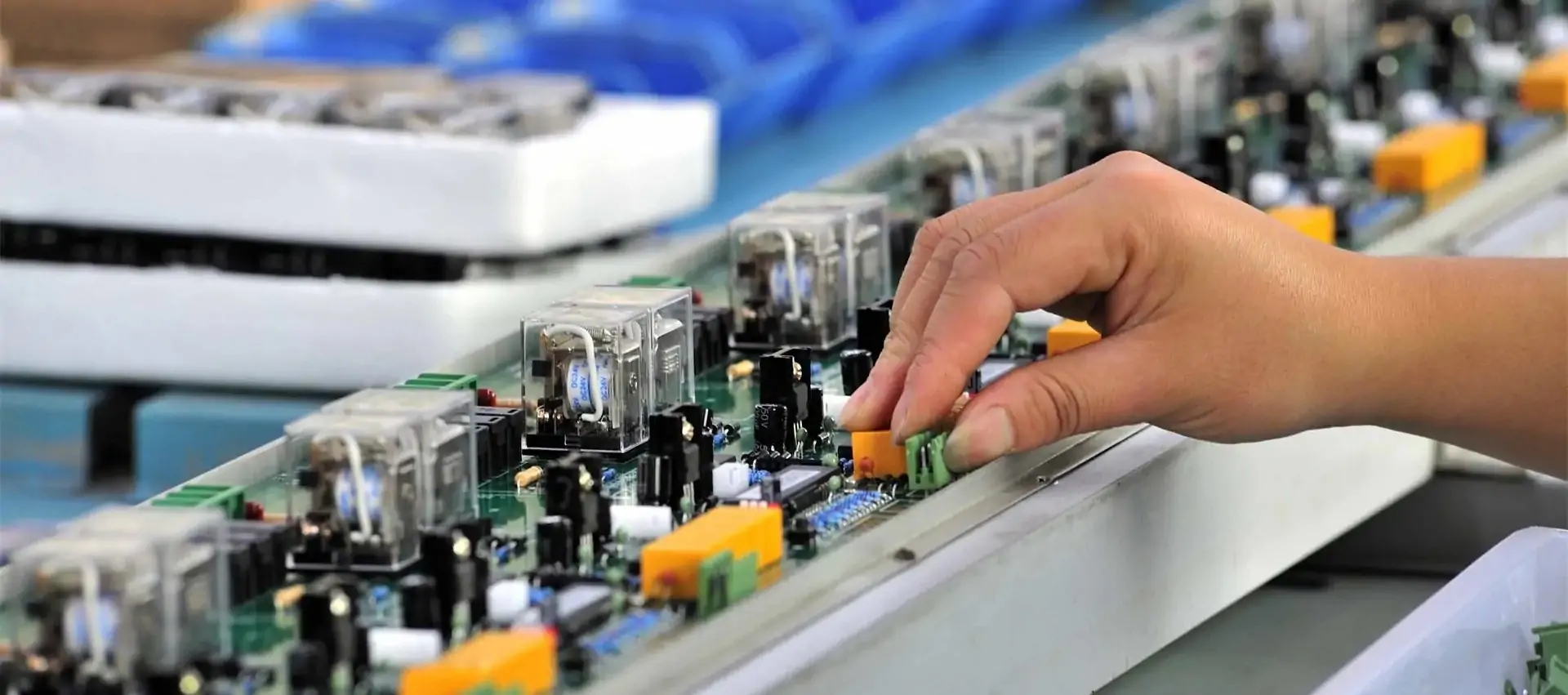

In the industrial control industry, PCBs and PCBAs are the core components of various types of automation equipment and control systems. PCBs provide a stable circuit foundation that ensures reliable signal transmission and high durability, while PCBAs integrate electronic components to realise complex control and data processing functions.

Serves as the core control system for production processes, handling automation and management.

Enables data display and user interaction, supporting operators in real-time monitoring and process adjustments.

Used for data collection and precise control in sensors and motor controllers to meet production requirements.

Facilitates motion control and feedback processing within robotic systems, enabling complex automation tasks.

Ensuring PCBA operates stably over the long term in harsh environments like high temperature, humidity, and vibration.

Using industrial-grade electronic components to guarantee precise control and data processing capabilities.

Optimized power layout and thermal management to ensure stable power supply and effective heat dissipation for the PCBA.

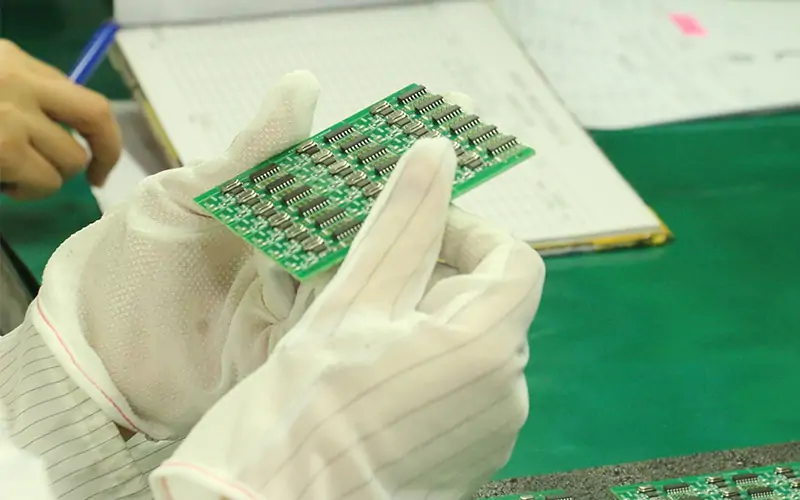

Rigorous functional testing and compliance with safety standards (e.g., UL, IEC) to ensure product quality and safety.

Used for programmable logic controllers (PLCs), human-machine interfaces (HMIs) and power management modules

Used for robotic systems and complex sensor modules.

For industrial control boards and embedded control modules.

Commonly used for motor drivers, high power LED lighting controls and power management devices with high heat dissipation.

PCBA is capable of performing complex automation control and data processing, which is suitable for PLC, HMI and other industrial control equipment.

Industrial control PCBAs are highly durable and suitable for long-time operation and high-load applications, thus improving the overall reliability of the equipment.

PCBAs are rigorously tested to meet UL, IEC and other safety standards to ensure safe operation in high-temperature, high humidity and strong interference environments.

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

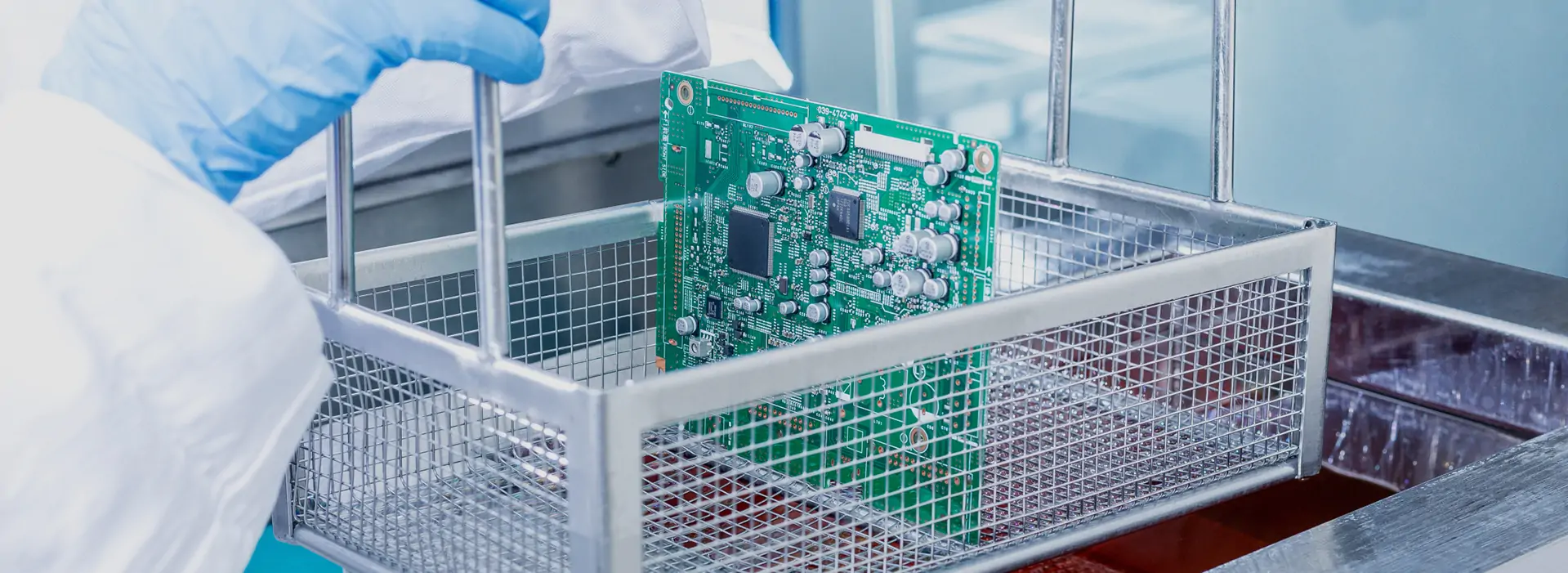

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.

For Industrial PCB Assembly Solutions, please contact online customer service.