IoT PCBAs are printed circuit board assemblies designed for Internet of Things (IoT) devices. These components play a critical role in the functionality, connectivity, and performance of IoT applications.

IoT PCBAs are critical to the development of connected devices that enhance efficiency, automation and user experience across multiple industries. By focusing on integration, low power consumption and security, HRPCBAs can help customers create reliable and effective IoT solutions to meet the growing demands of the Internet of Things.

HRPCBA can provide strict quality control and testing processes to ensure the long-term stability and performance of PCBAs under different environmental conditions.

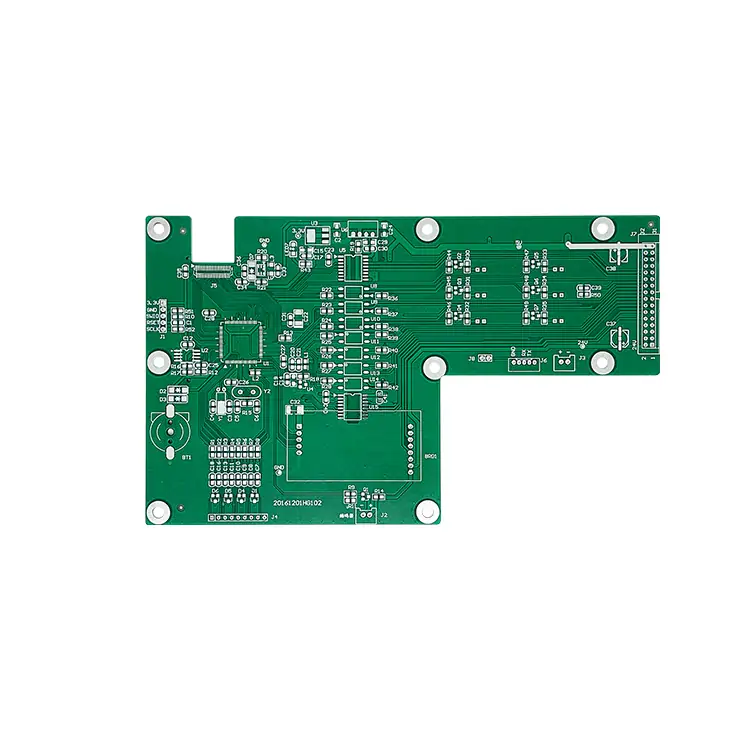

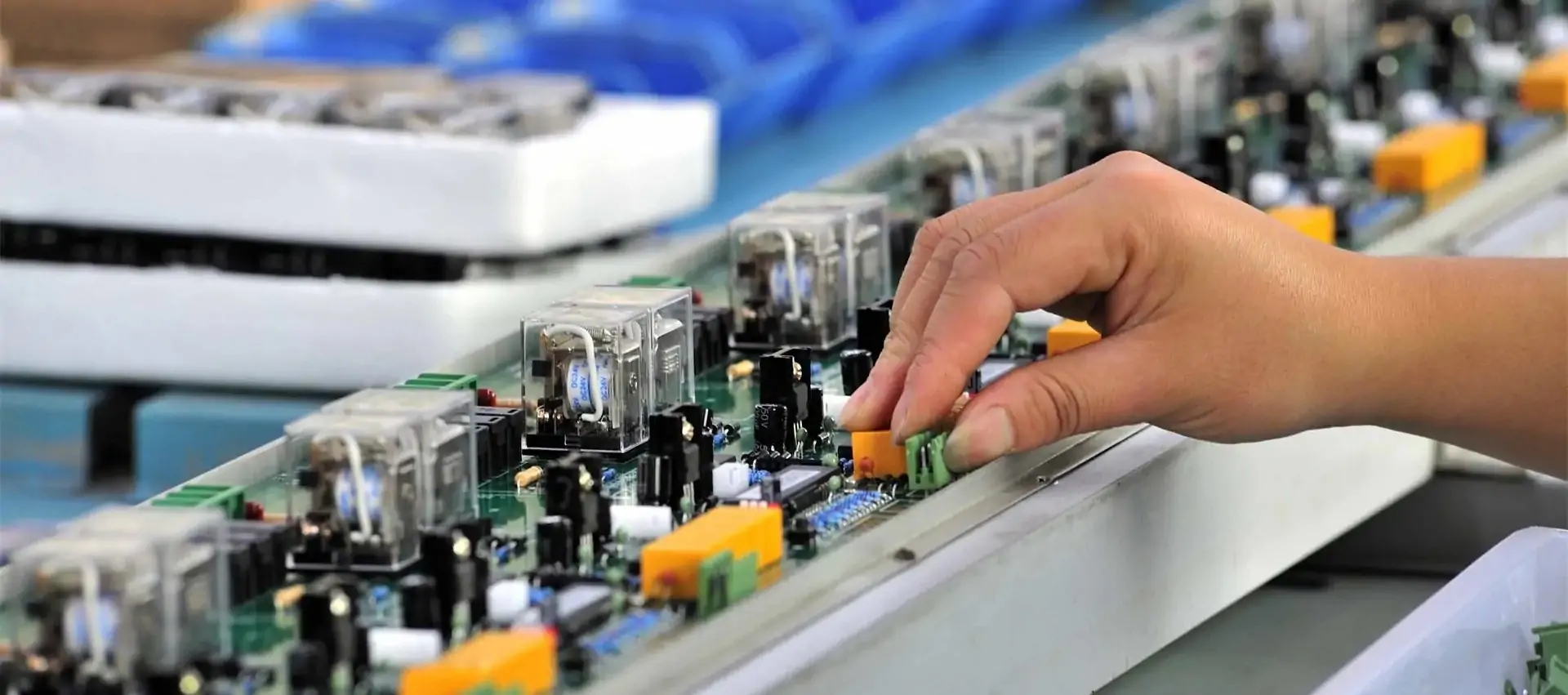

HRPCBA can customise the PCBA according to the gerber file provided by the customer, and we can provide flexible production capacity and customisation services to meet the needs of customers for different products.

Security is critical for IoT devices.HRPCBA can provide security design and implementation measures to protect devices from potential cyber attacks and data leakage.

HRPCB produces PCBAs that comply with relevant industry standards and certifications (e.g. CE, FCC, RoHS, etc.) to ensure the legitimacy and safety of customers' products in the market.

Used in fitness trackers and health monitoring devices to collect data on user activity and health metrics.

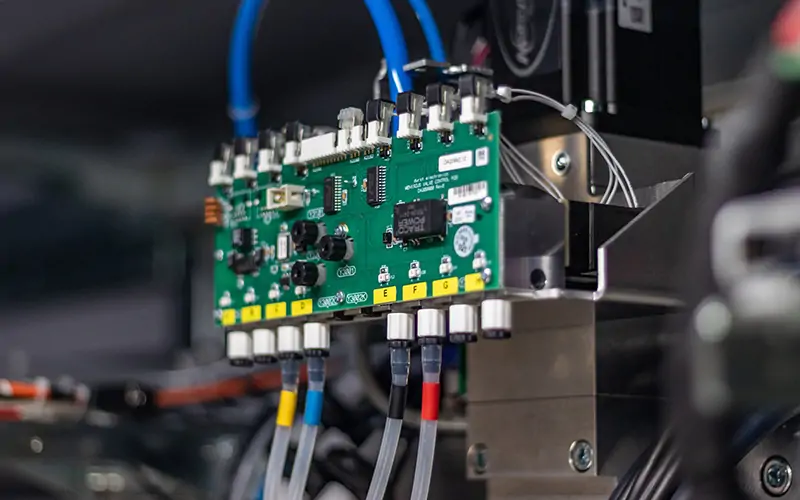

Applications for real-time monitoring, predictive maintenance and process automation of machinery and equipment.

Sensors and monitoring systems for monitoring soil moisture, weather conditions and crop health for precision agriculture.

Integration into automotive applications for telematics, vehicle tracking and advanced driver assistance systems (ADAS).

Used for visual inspection to automatically identify component placement, solder quality and other physical defects on the PCB.

Tests the various functional modules of the PCBA to ensure their proper operation in actual use, usually including specific test fixtures and equipment.

Conducts temperature and humidity tests to evaluate the performance of PCBAs in extreme environmental conditions and ensure the stability of the equipment in different environments.

Includes insulation testers and grounding testers to ensure the safety and stability of circuits and check electrical performance.

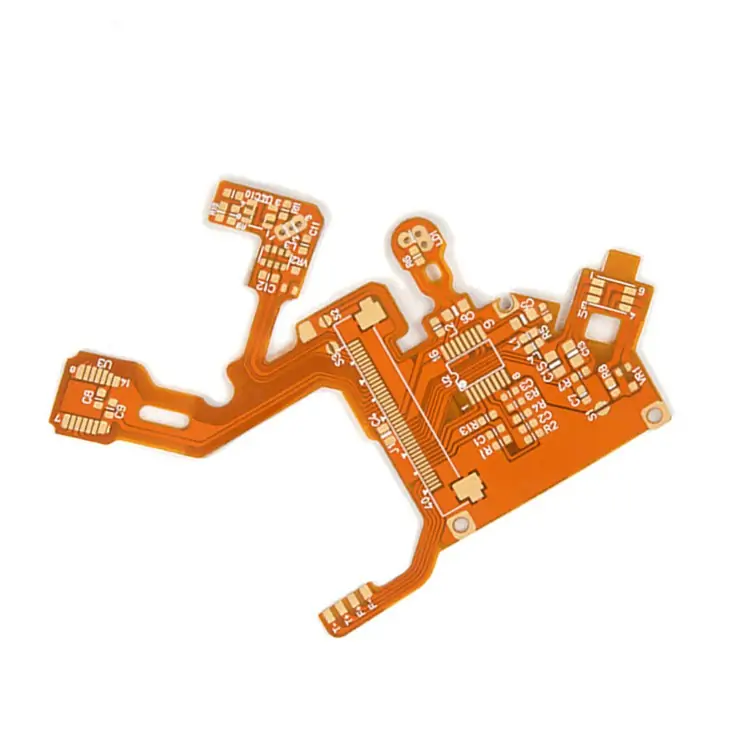

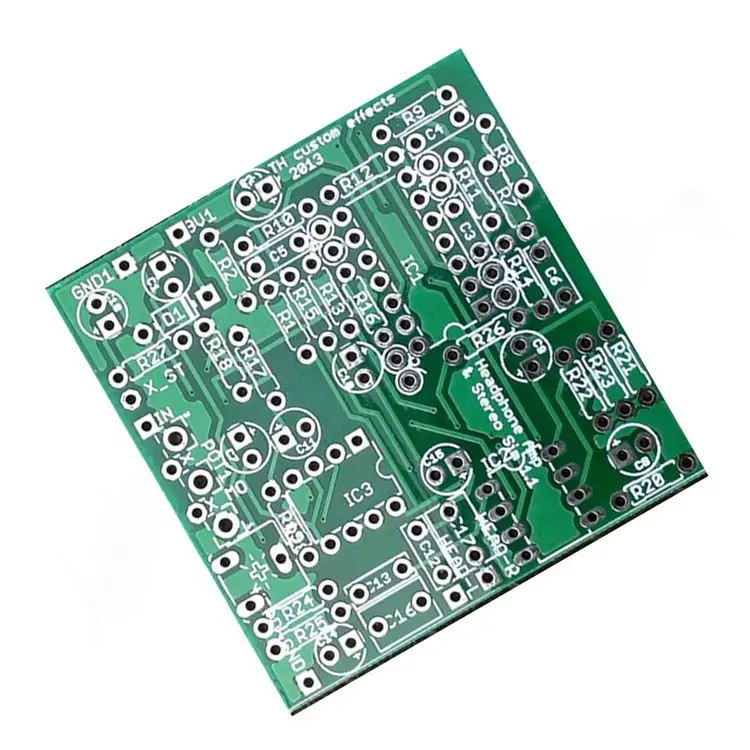

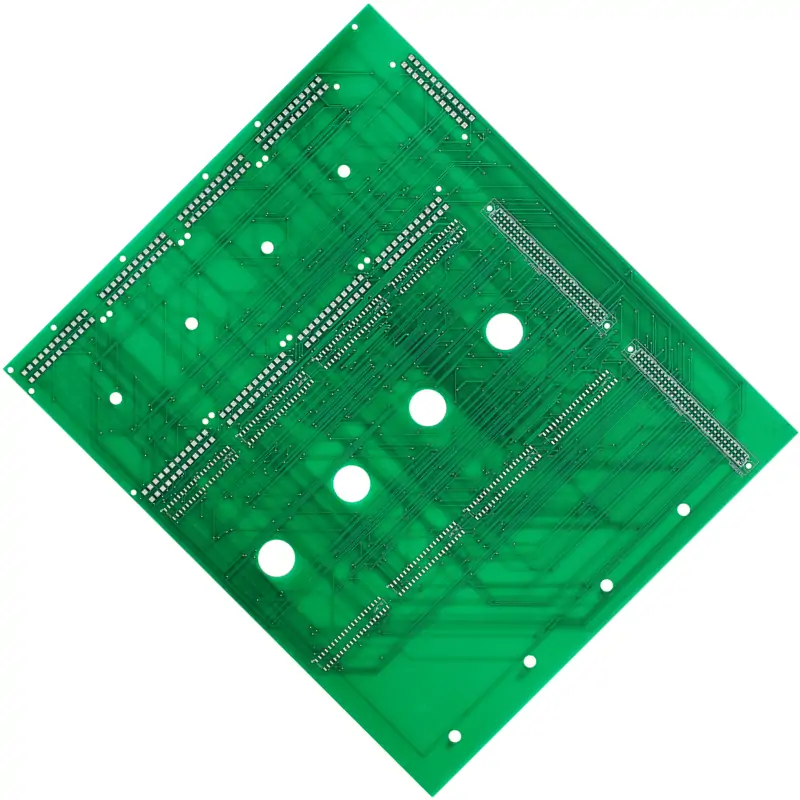

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.

HRPCBA, a reliable IoT PCBA solution provider.