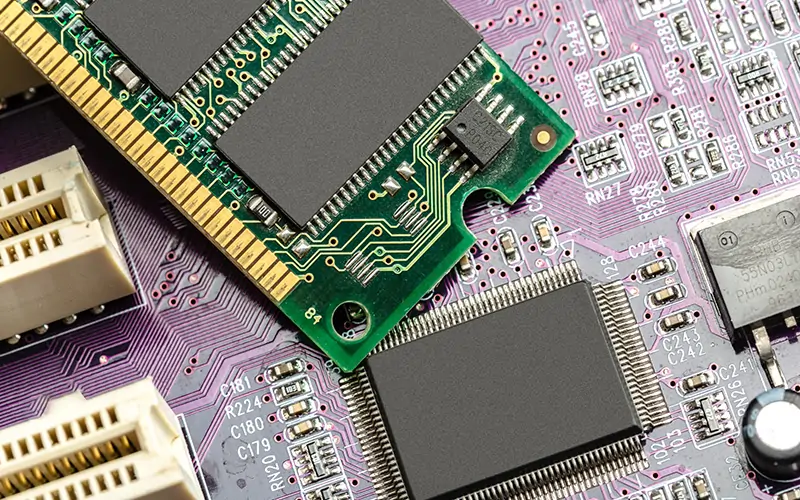

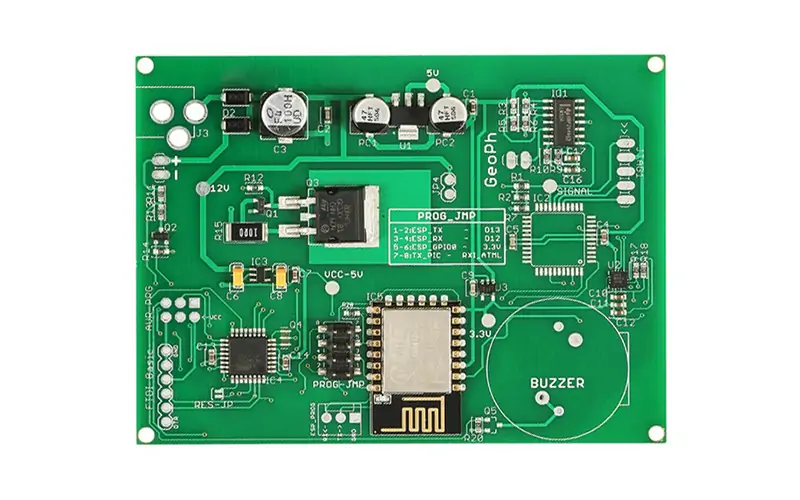

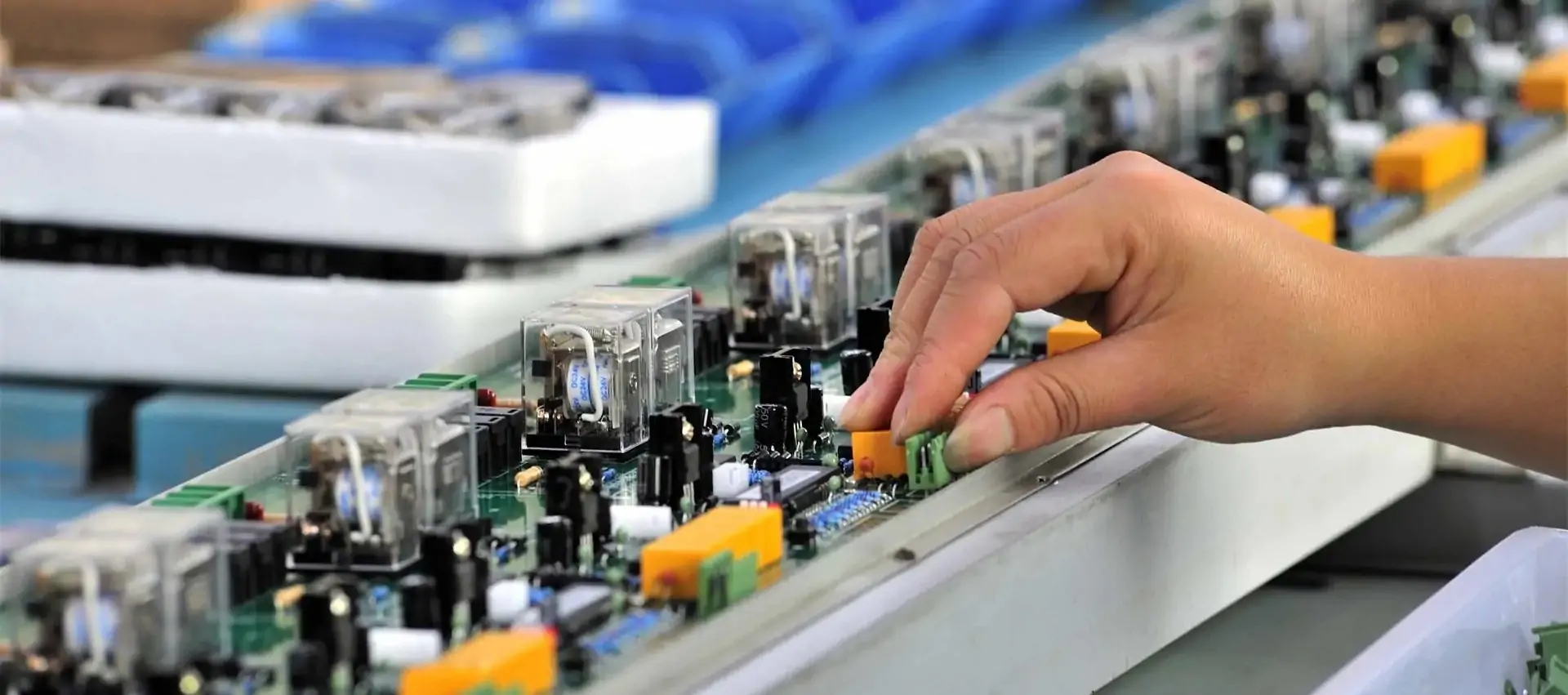

Intelligent Security PCBAs are printed circuit board assemblies designed for intelligent security devices. They are widely used in home and commercial security systems, including surveillance cameras, intrusion detection systems, access controllers, and more.

Ensure encryption of data transmission and storage, and integrate secure authentication mechanisms to prevent unauthorised access and cyber attacks.

Implement a rigorous testing process that includes functional, environmental and electrical testing, and select high-quality components to ensure reliability.

Design low-power solutions to extend battery life and optimise PCB design to ensure good signal transmission and wireless communication compatibility.

Conduct environmental testing to validate product performance, ensure compliance with relevant industry standards and certifications, and maintain good documentation to safeguard compliance.

Used for real-time video surveillance and recording in homes or commercial premises with motion detection, night vision and cloud storage.

Integrated sensors monitor intrusion activity and notify users through an alarm system to ensure home or business security.

Used to control access control access, supports fingerprint identification, password input or mobile app control for improved security.

Monitor the environment in real time through sensors and cameras, and notify users via SMS or APP when abnormalities occur.

Checks the quality of component placement and soldering while verifying that all functional modules, such as cameras and sensors, are working properly.

Perform environmental tests such as temperature, humidity and vibration to ensure PCBA stability under extreme conditions, as well as insulation and grounding tests to ensure electrical safety.

Evaluate the durability of products through accelerated aging tests to ensure their reliability in long-term use. Also, test the performance of PCBAs under electromagnetic interference and radio frequency interference.

Verify whether the PCBA complies with relevant safety standards to protect users from potential hazards, and test the function and operation of embedded software and firmware.

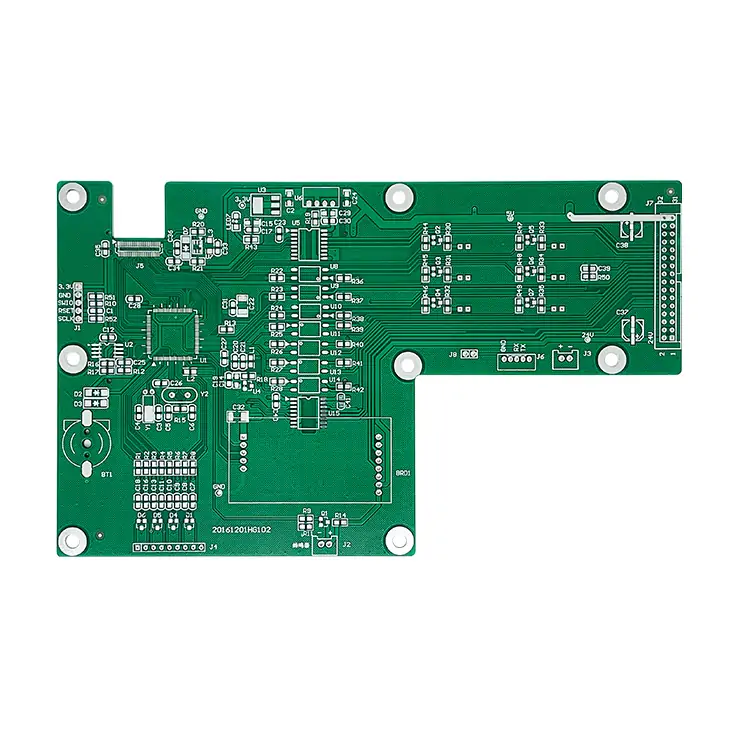

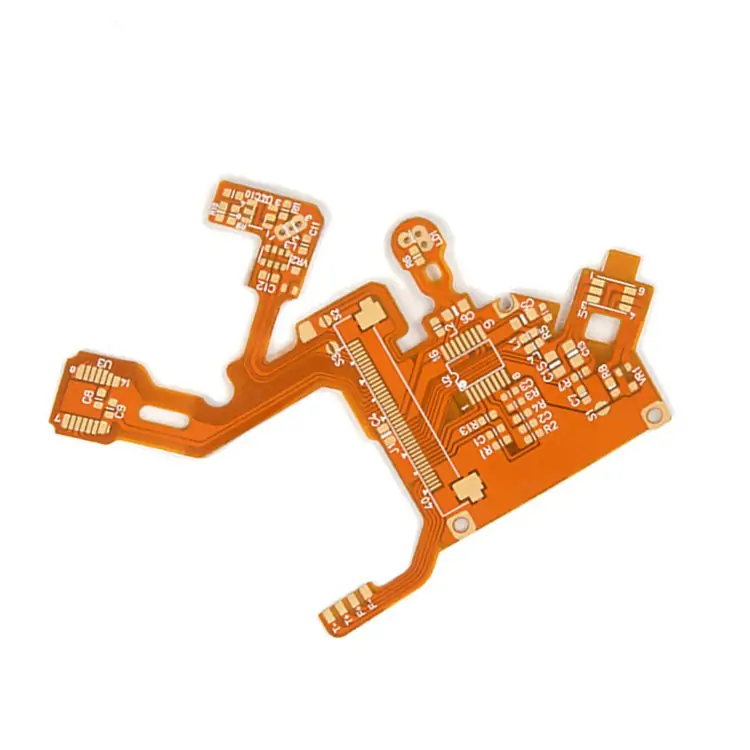

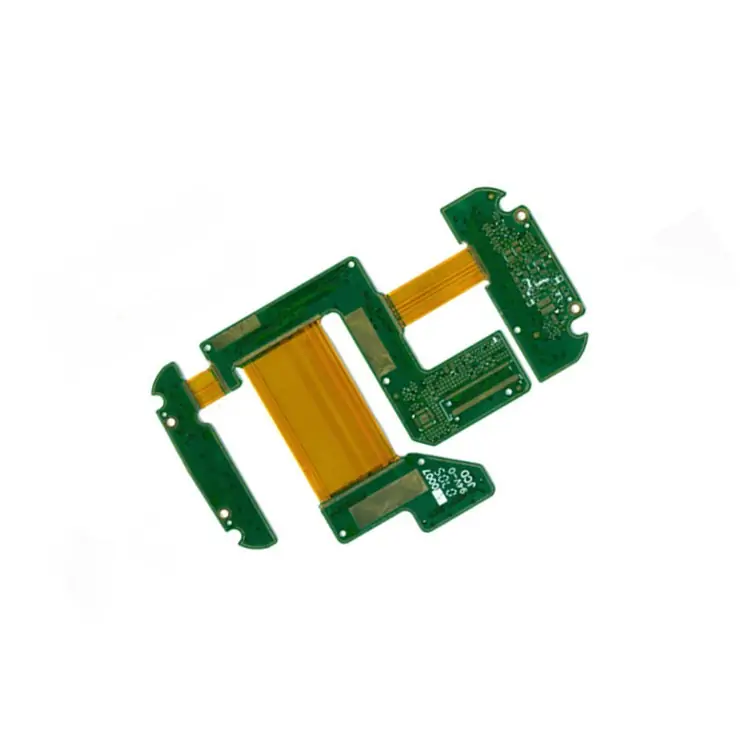

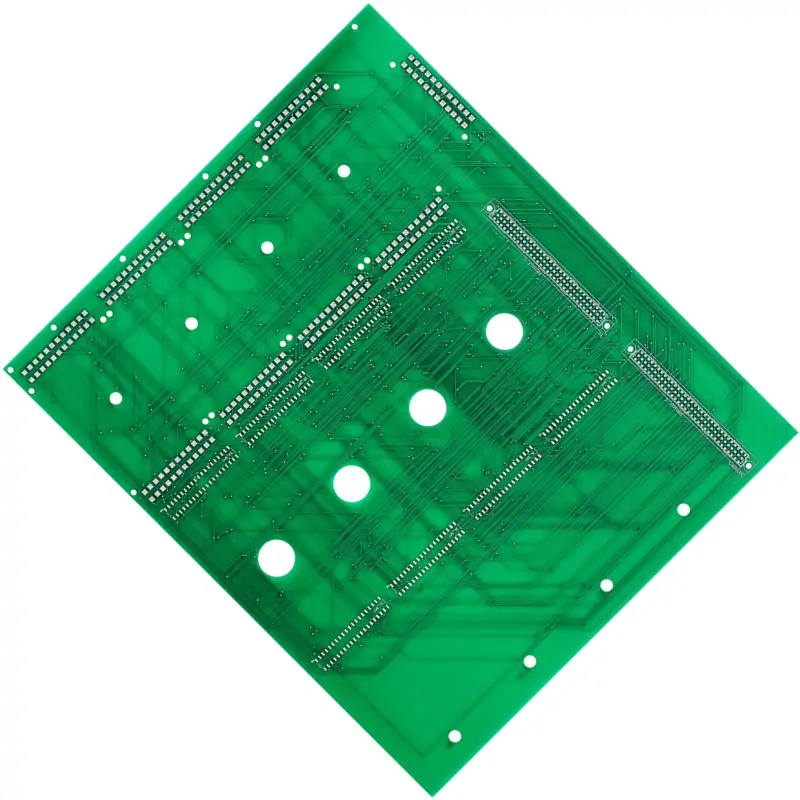

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.