Medical PCBA plays a key role in medical devices and directly affects the performance, reliability and safety of the device. This requires that medical PCBAs need to meet strict quality standards such as ISO 13485 and FDA.

With the development of the medical industry and market changes, there is an increased demand for portable and intelligent medical devices. This has also prompted the technology update of medical PCBA.

High-quality PCBA design improves the reliability and safety of devices, supports intelligent features such as remote monitoring and data transmission, and enhances the efficiency of medical services.

Electrocardiographs, ultrasound equipment, magnetic resonance imaging (MRI), etc. These devices have extremely high requirements for signal processing, accuracy and reliability.

Sphygmomanometers, blood glucose meters, pulse oximeters, patient monitors, etc., which are used for real-time monitoring of patients' physiological parameters.

Dialysis machines, infusion pumps, defibrillators, ventilators and other equipment, requiring PCBA with high stability and reliability.

Such as pacemakers, neurostimulators and other implantable devices, PCBAs are required to have extremely low power consumption, miniaturization and biocompatibility.

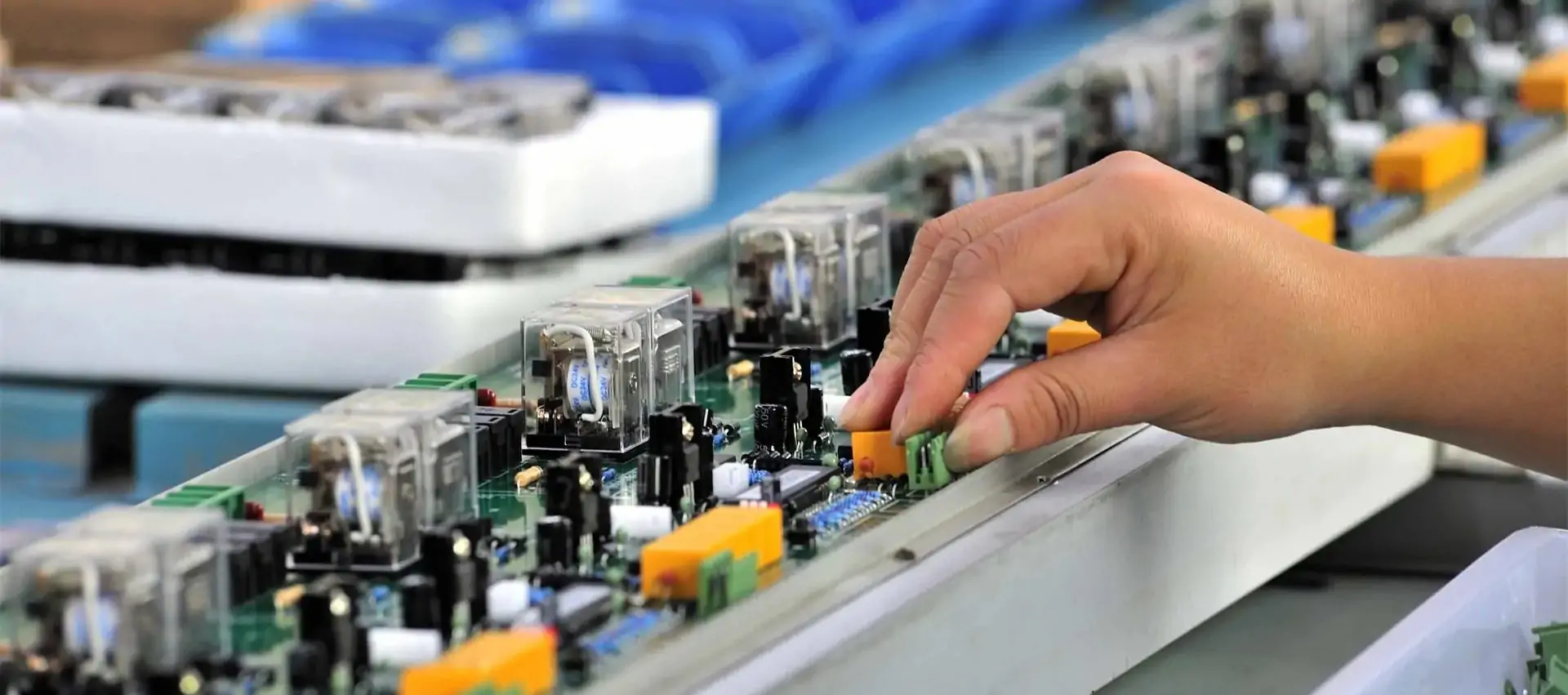

Strict quality management system is the basis for ensuring the reliability and safety of medical PCBAs, which strictly follows the production standards of ISO, IPC-A-610D-G, ROHS, etc.

High quality materials that meet medical industry standards, such as lead-free solder and biocompatible materials, are used to ensure the safety and durability of PCBAs.

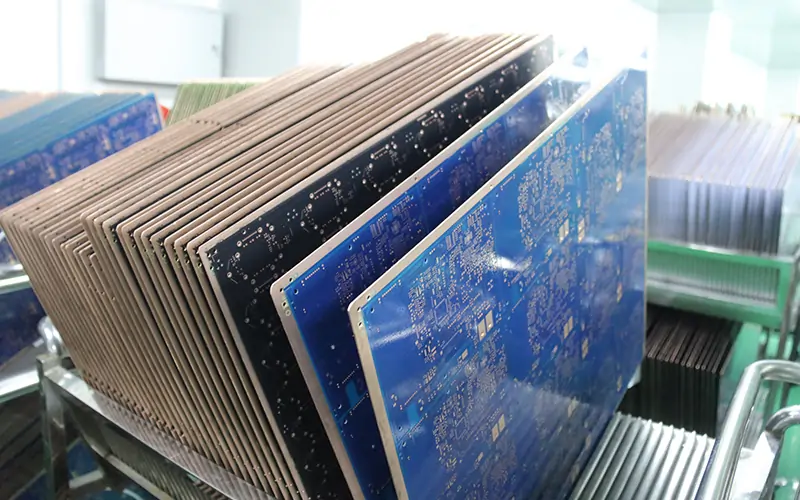

Conduct comprehensive functional tests, including electrical, functional and environmental tests, to ensure product stability and reliability.

Ensure all PCBA products comply with relevant regulations and standards (e.g. FDA, CE, etc.).

Quickly detect visible defects, detect soldering quality, component location and PCB surface defects.

Flexible electrical testing with removable probes to ensure circuit connectivity and proper functioning.

Verify the function of PCBA under actual operating conditions

Checking the quality of soldering inside printed circuit boards and the assembly of complex components.

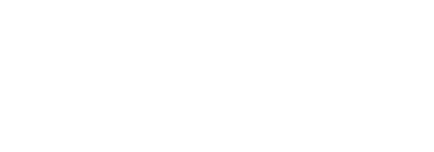

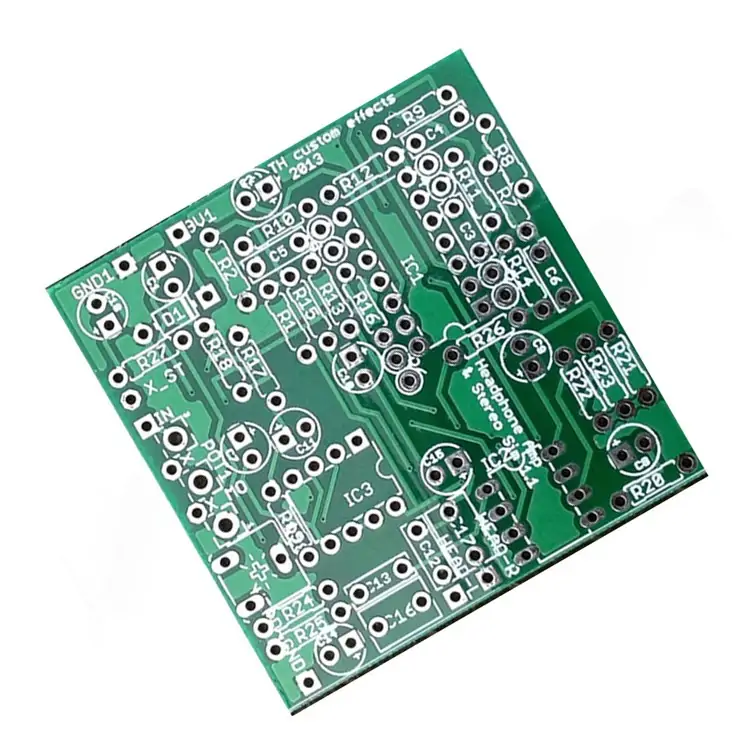

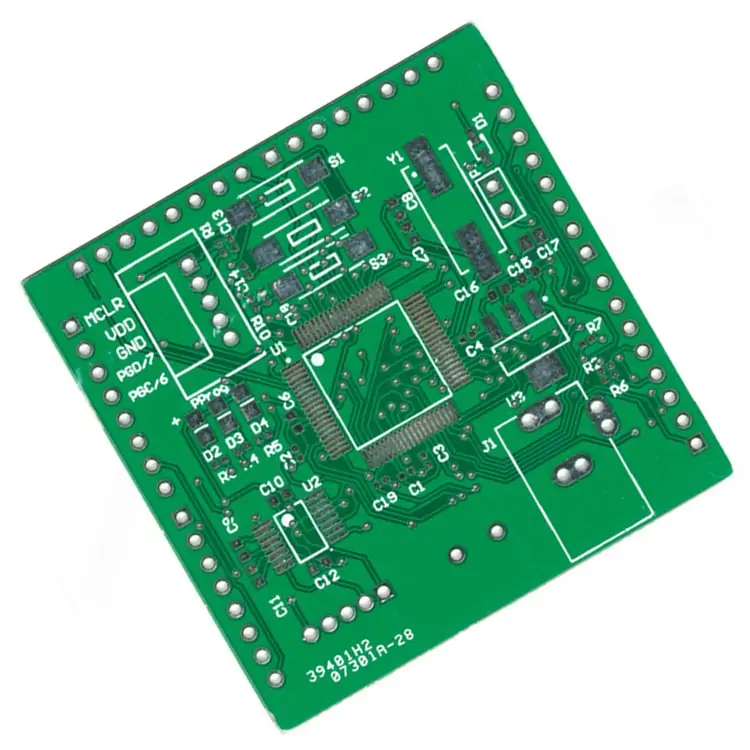

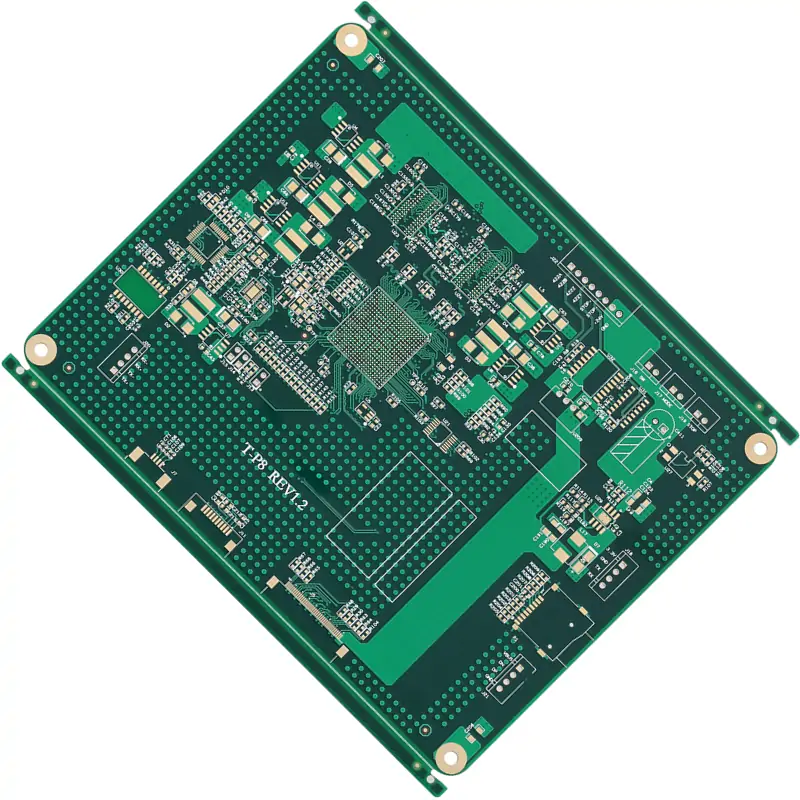

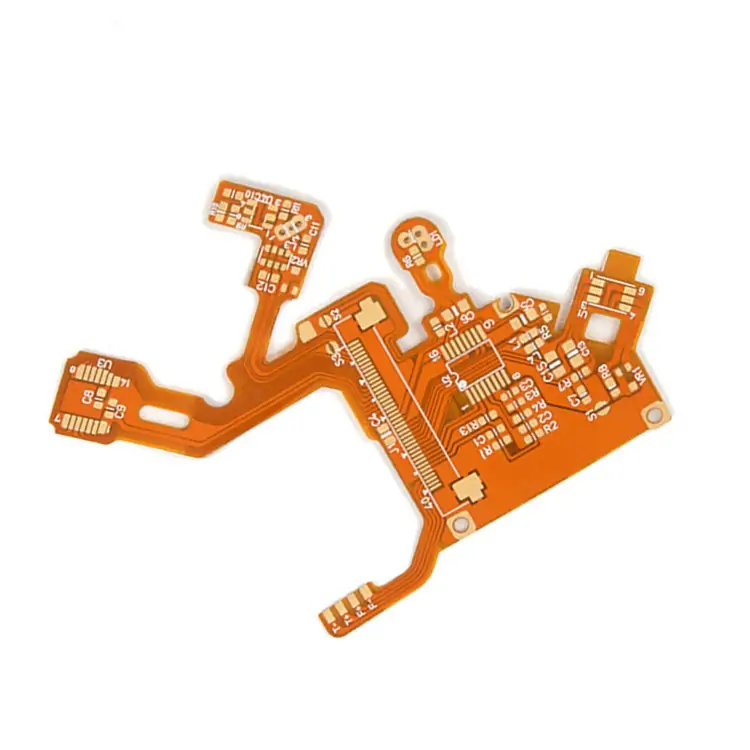

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.

Trust HRPCBA's high-precision PCB solutions for medical equipment PCBA, delivering top-tier performance for life-saving healthcare technology.