Military PCBAs are critical components that ensure the functionality, performance and safety of military equipment and must meet stringent standards and requirements during the design and manufacturing process.

PCBAs are used in a wide range of military systems and equipment, such as weapons systems, communications equipment, navigation instruments and drones.

A comprehensive quality management system is implemented to ensure that every aspect of production meets military standards.

Design and selection should ensure that the PCBA can operate under extreme environmental conditions, using suitable materials and components.

PCBAs must have good immunity to electromagnetic interference (EMI) to ensure reliable operation in complex electromagnetic environments.

The production process of military PCBAs requires strict quality control. hrPCBA conducts thorough testing of the product to ensure that the PCBA meets all specifications before it leaves the factory.

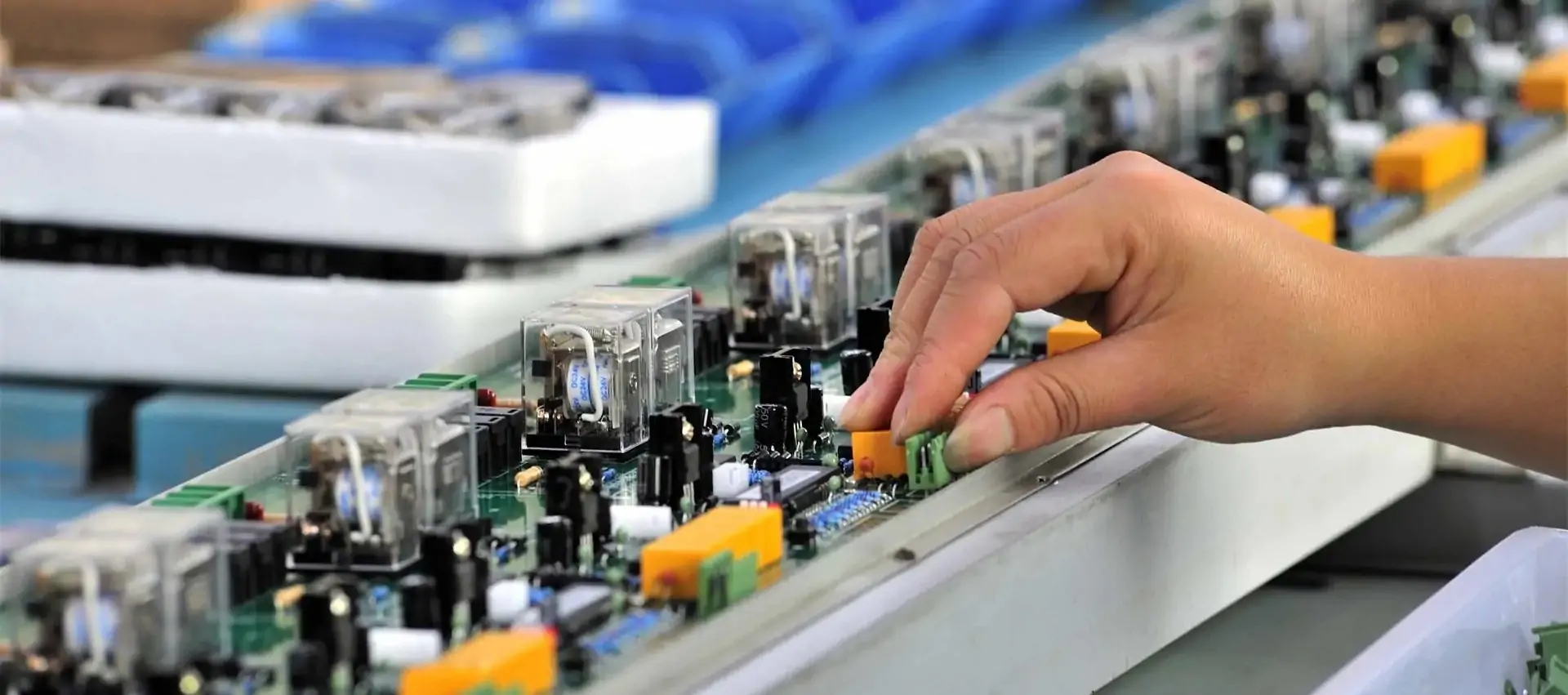

Manufacture PCB according to customer's gerber file. Procurement of components according to BOM LIST to meet quality standards.

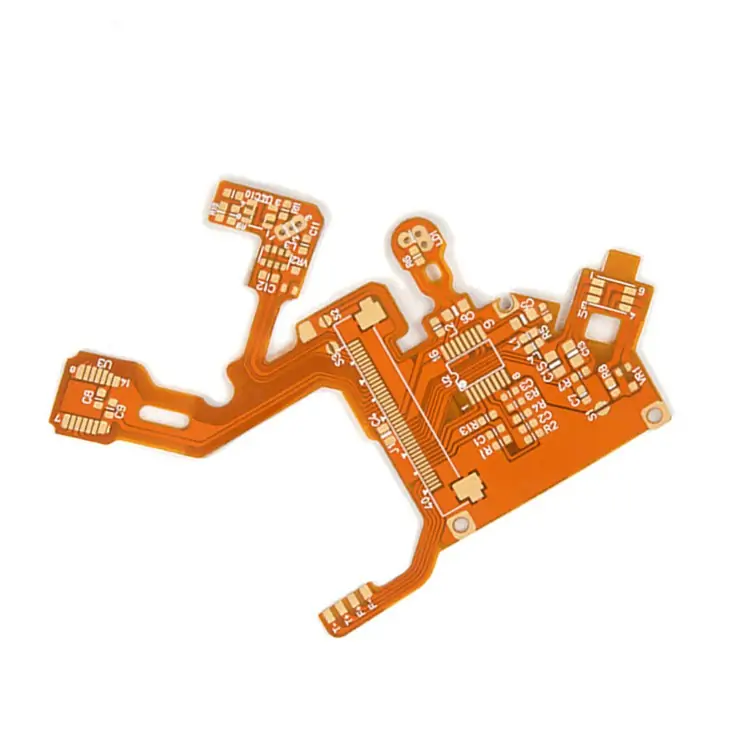

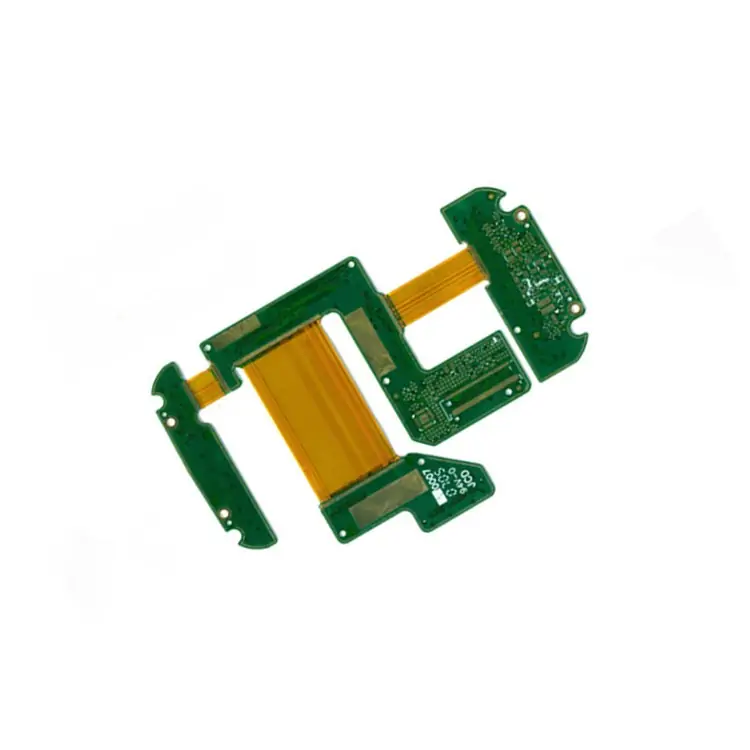

Surface mount technology (suitable for high-density, miniaturised component arrangement, the most commonly used assembly method in consumer electronics) Through-hole technology (THT is used on some components that require high strength connections)

Reflow soldering or wave soldering is performed to fix the components on the board and complete the soldering.

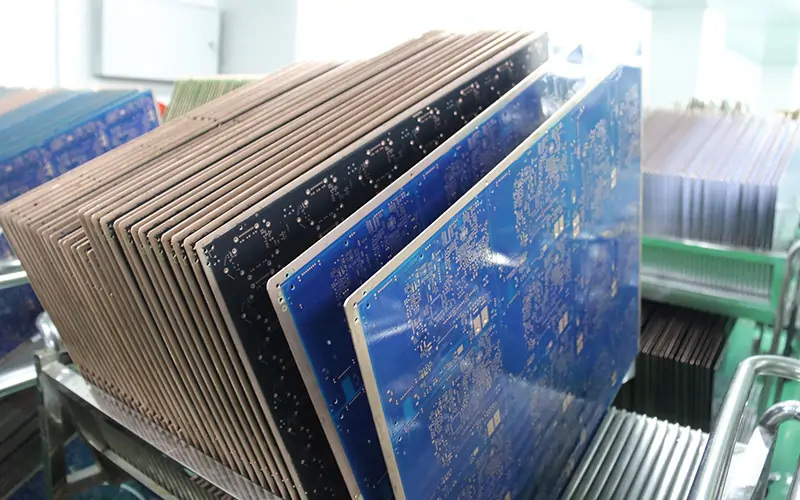

In order to ensure the quality of PCBA, HRPCBA will do a series of tests on the products, including automatic optical inspection (AOI), X-ray inspection, functional test and in-line test, etc. to find and eliminate possible faults.

Verifies the overall functionality of the PCBA to ensure that all circuits and modules work as designed.

Detects the mounting and function of each component on the PCB, including component values, connectivity, shorts and opens.

Detects surface defects, including component offset, missing, misalignment, solder joint defects, etc., and identifies potential problems through image analysis.

Detects the quality of solder joints in BGAs and multi-layer PCBs, checking the soldering for false soldering, cracks and internal connection problems to ensure the integrity and reliability of the internal structure.

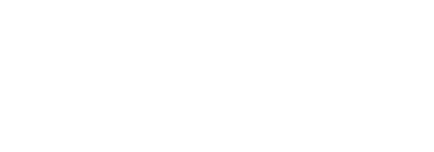

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.