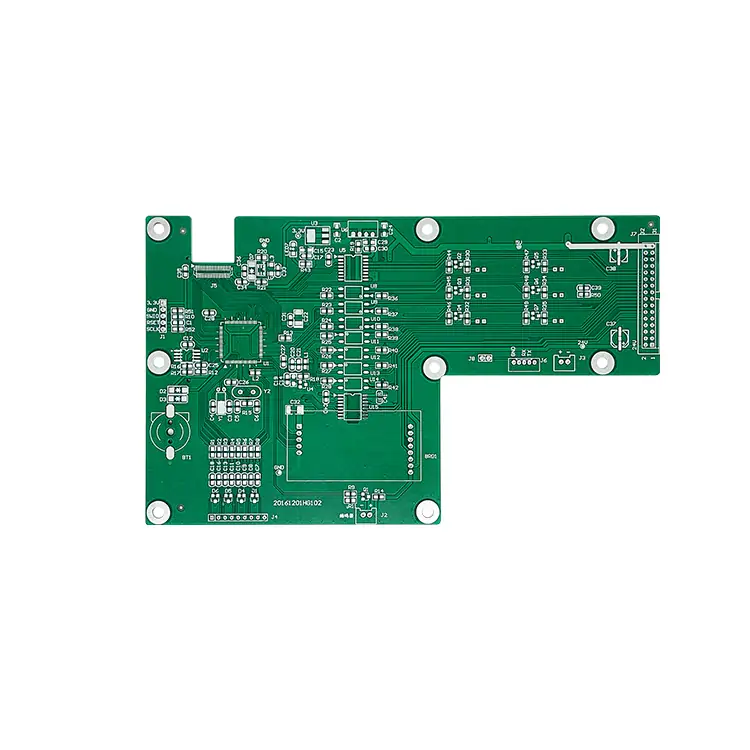

Smart home PCBA carries the control, communication and data processing functions of the device..

By integrating multiple functions and communication capabilities, it enhances user experience and home automation. The reliability, security and low-power design of smart home PCBAs make smart home solutions more practical and convenient

Smart home PCBAs often integrate multiple functional modules such as Wi-Fi, Bluetooth, sensor interfaces and processors to support the multiple functions of the device.

Low-power components and designs are used to extend the life of battery-powered devices, such as smart door locks and smart sensors.

Supports wireless protocols (e.g., Zigbee, Z-Wave, Wi-Fi, Bluetooth) to interconnect devices for remote control and data transfer.

Encryption and secure authentication mechanisms are included in the design to ensure the security of user data and device control against hacker attacks.

Used for smart lamps and lighting control systems, allowing users to control lighting via mobile apps or voice assistants.

Smart door locks, surveillance cameras and intrusion sensors, with remote monitoring and alarm functions via PCBA.

Smart thermostats, PCBAs control the home's heating and air conditioning systems to optimise energy use and living comfort.

Smart speaker or home control centre, PCBA is used for voice recognition, data processing and device management to achieve centralised control of various smart devices

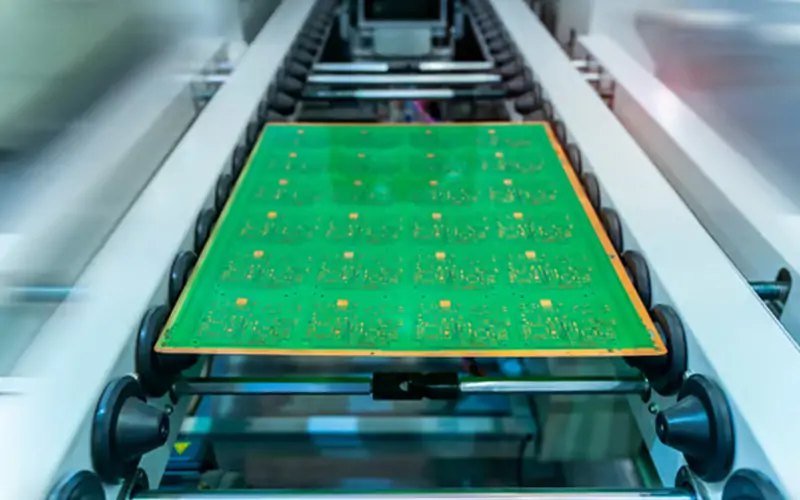

High-quality components are selected and rigorous testing and quality control are performed to ensure that PCBAs can operate stably for a long period of time under different environmental conditions (e.g., temperature, humidity, and vibration).

Optimise the production process and improve production efficiency to ensure that we can respond quickly to changes in market demand and customer customisation needs, and shorten lead times.

Considering the diversity of smart home devices, ensure that the PCBA design has a certain degree of flexibility to adapt to the functional requirements and form factor of different products.

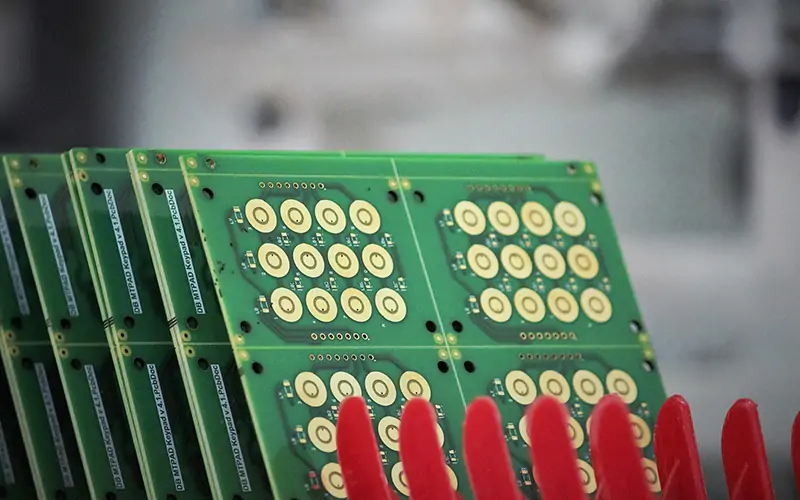

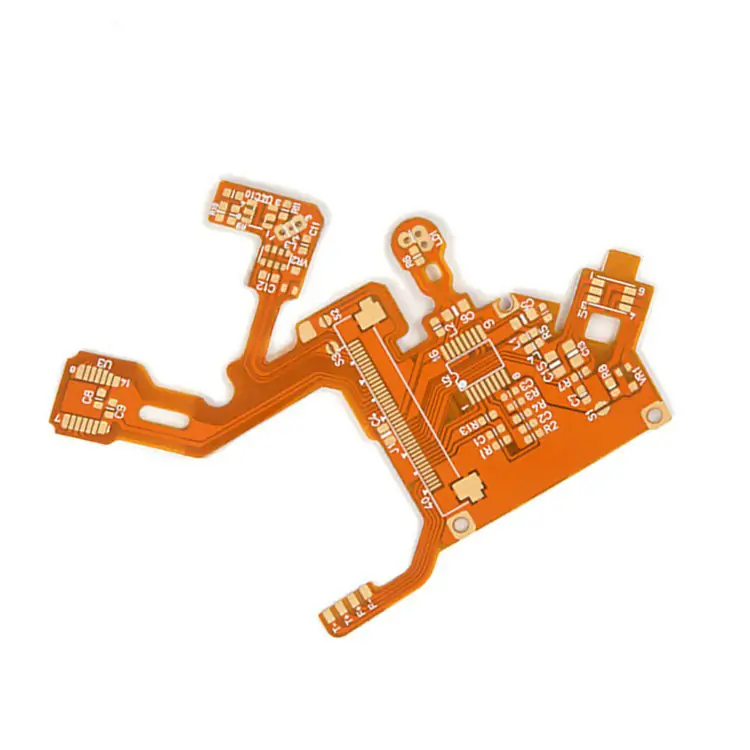

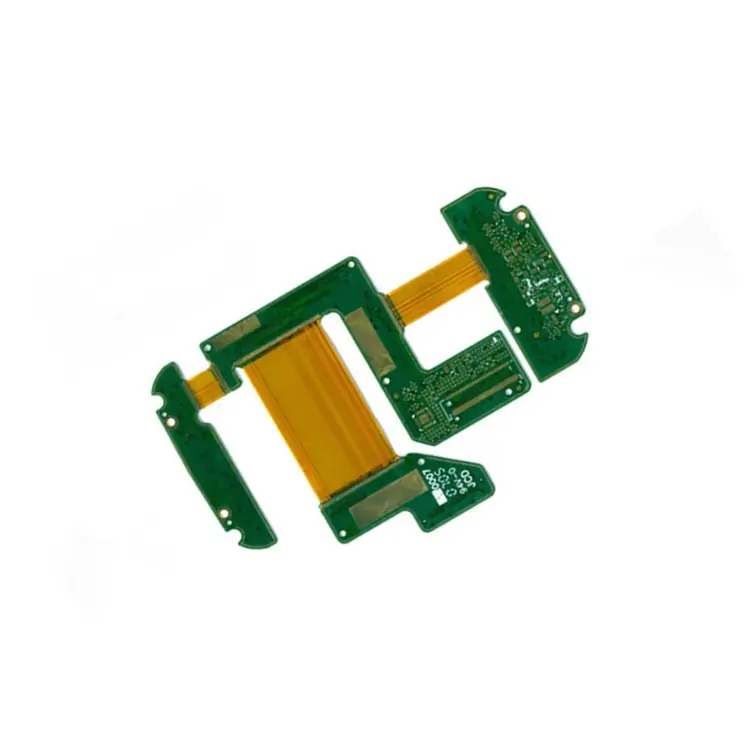

We can provide various types of circuit boards such as Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, Copper PCBs and High Density Interconnect PCBs.

All components are manufactured to IPC-A-600F Class 2 and Class 3 standards or better. We have specialized pcb manufacturing and testing equipment for medical devices.

We use high quality materials, advanced manufacturing processes and rigorous testing to ensure stable and trouble-free operation of medical devices.

Regular testing, quality assurance processes and adherence to industry standards are critical throughout the design and manufacturing stages. All printed circuit boards are subjected to ICT, Automated Optical Inspection (AOI), X-ray, Functional Test (FCT) and aging tests prior to shipment.