Verify product functionality: Ensure that every function of the PCBA is working as designed. Detect Defects: Identify and fix design or manufacturing problems at an early stage to avoid rework or failures at a later stage.

Improve Reliability: Ensure the stability and reliability of PCBAs through repeated testing.

Our engineering team and company founders are highly skilled and respected with over 25 years of industry experience, which ensures that you will receive a PCBA product that perfectly meets your requirements.

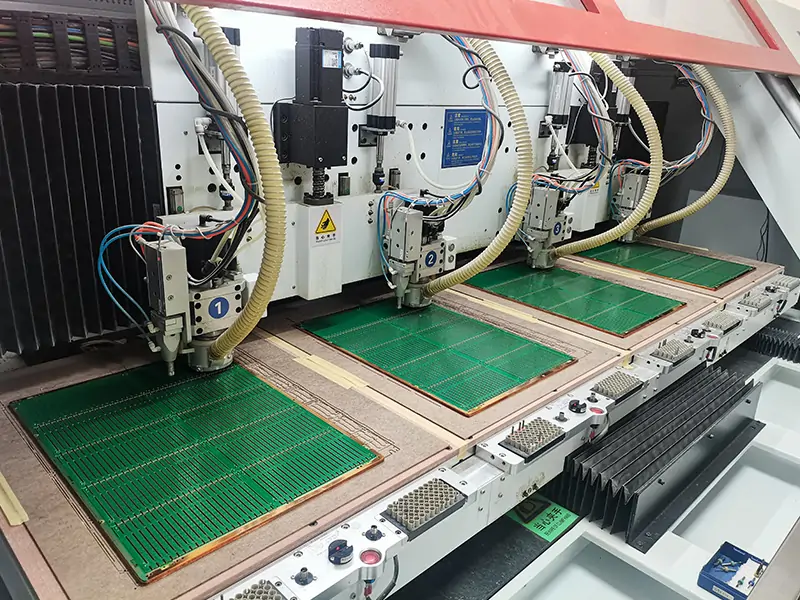

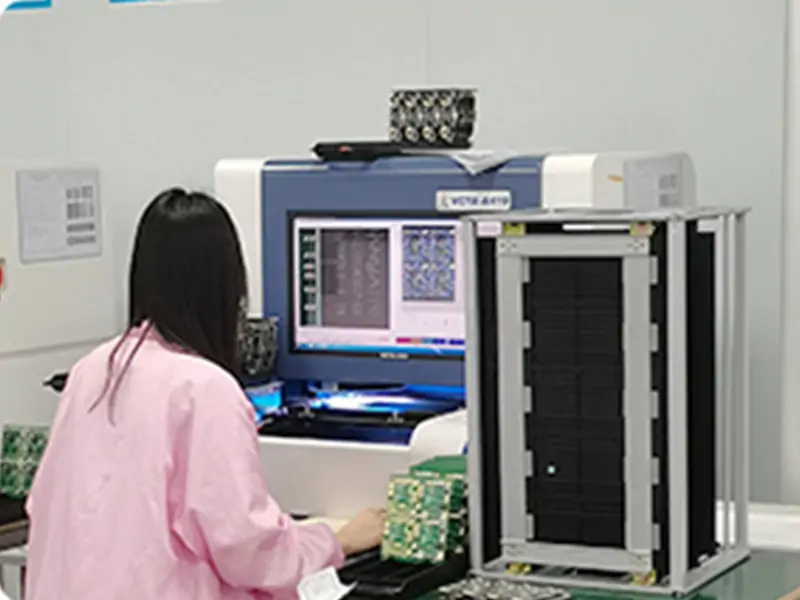

Our state-of-the-art SMT and THT production lines provide a full range of services from PCB design and component sourcing to assembly and testing, ensuring fast delivery of high quality products.

Functional testing is the verification and validation of the hardware and software functionality of an electronic product or system to ensure that it operates properly as designed.

Functional testing can help detect and correct problems in design, pcb manufacturing or programming to improve the reliability and performance of PCBAs.

Functional testing can find out the problems that may occur in PCBA under different use conditions, and improve the stability and reliability of PCBA through timely repair and optimization.

Helps to identify potential problems at an early stage.

Functional testing is an important part of the quality control process. Through rigorous testing and documentation, it ensures that each batch of PCBAs meets the same functional and performance standards.

In some regulated industries (e.g., medical, aerospace, telecommunications, etc.), products need to meet specific standards and specifications.

Functional testing not only identifies functional problems with a product, but also provides feedback through test data to help engineers optimize the design.

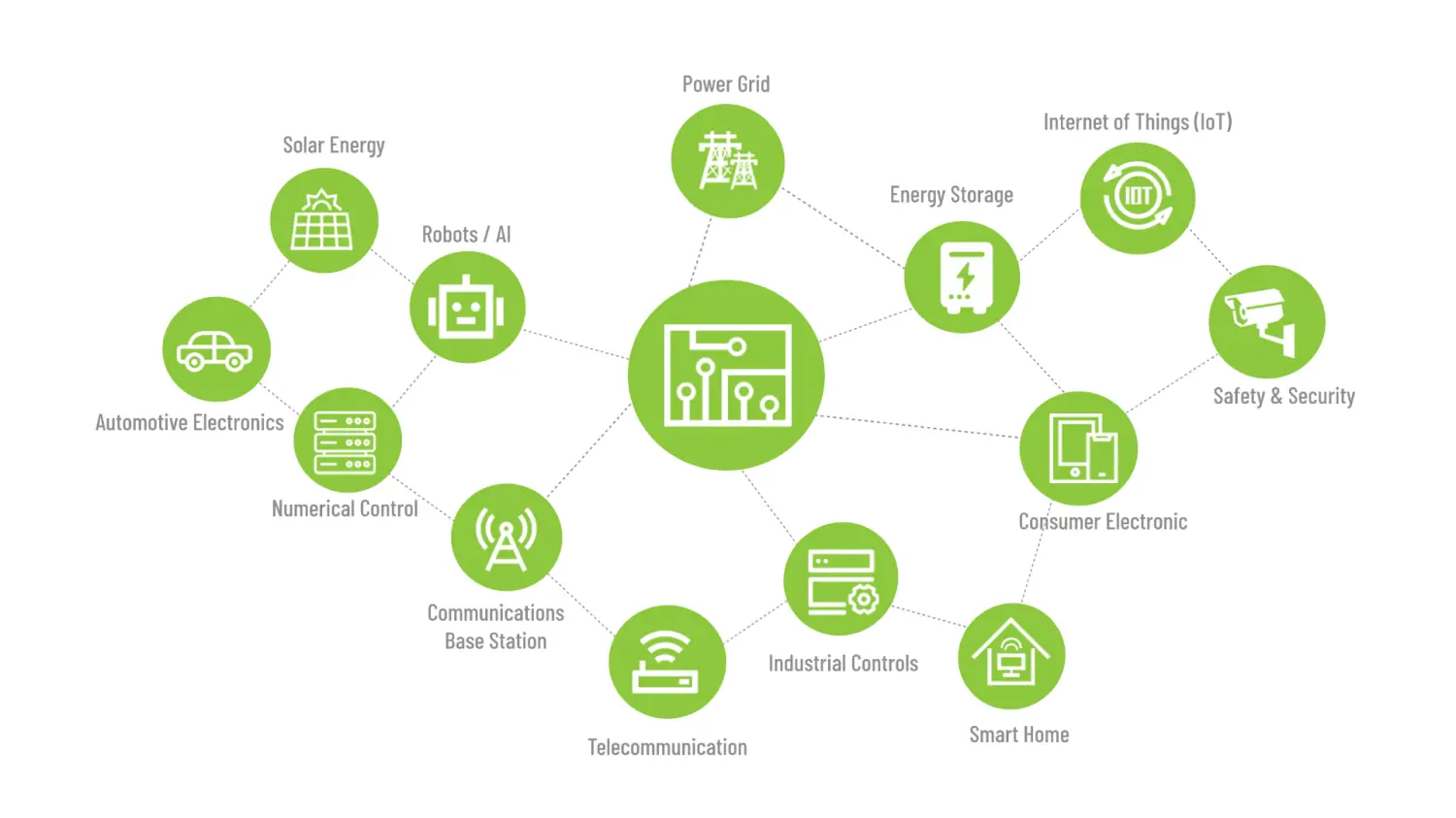

Medical electronics, automotive electronics, military electronics, industrial electronics, consumer electronics, communication electronics, smart home, ITO, security electronics, etc.

Provide your idea and requirements for your product

Brainstorming with each otherand defining the product

Design schematic diagram

Layout and simulation

Prototyping and sample Testing

Confimmation sample we will arrange bulk production

With 25 years of development, HRPCBA turns into a first classManufacturer of PCB and PCBA ssembly. We provide ourcustomersWith PCB solutions and services worldwide.especially more than 90%Printed circuit board are exported tooversea market

One-Stop Contract Manufacturing Services

Competitive Price in Peer Industry

4 Hours Quotation,2 Days Delicery,24 Hours customer Services

Strict Quality Control With 100%

Sales Network Covers Over Morethan 180 Countries And Regions

Efficient and Professional International Sales Team